News

Analysis on the EV Charging during Chinese Spring Festival

February 15, 2023

The annual Spring Festival is accompanied by the annual Spring Festival transportation. The problem of charging electric vehicles for long-distance driving has always been an indelible pain for car owners. Although the cruising range of electric vehicles and the construction of charging infrastructure have made great progress in recent years, the distance of more than 500 kilometers often makes the journey home a little more anxious.

01 The trend of liquid cooling supercharging

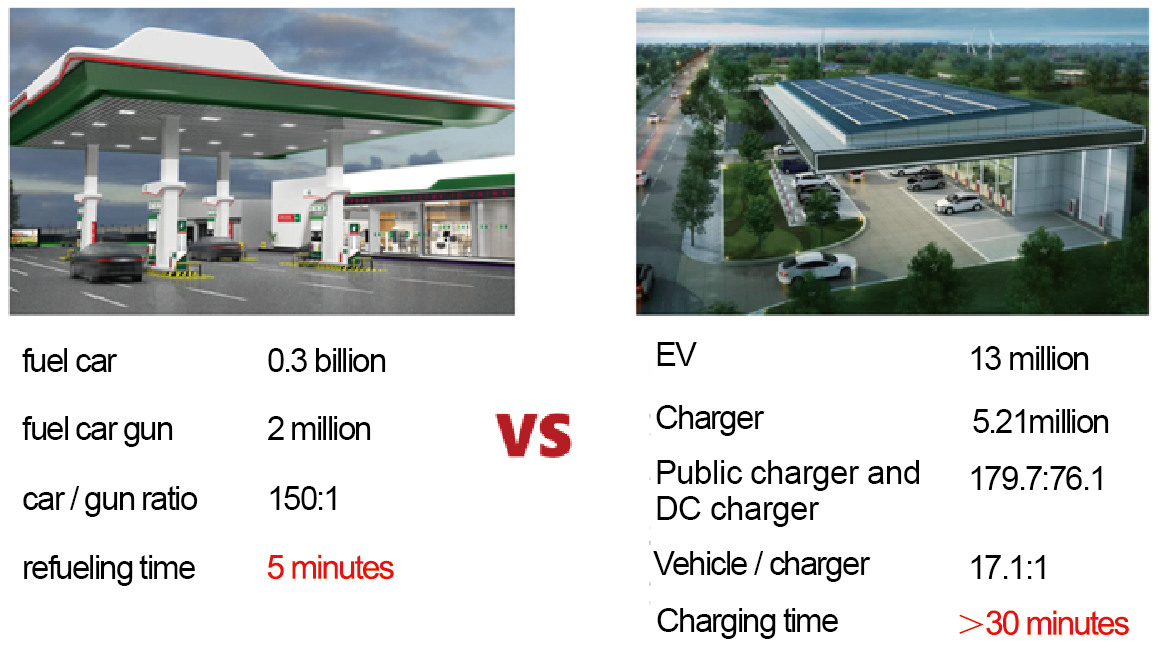

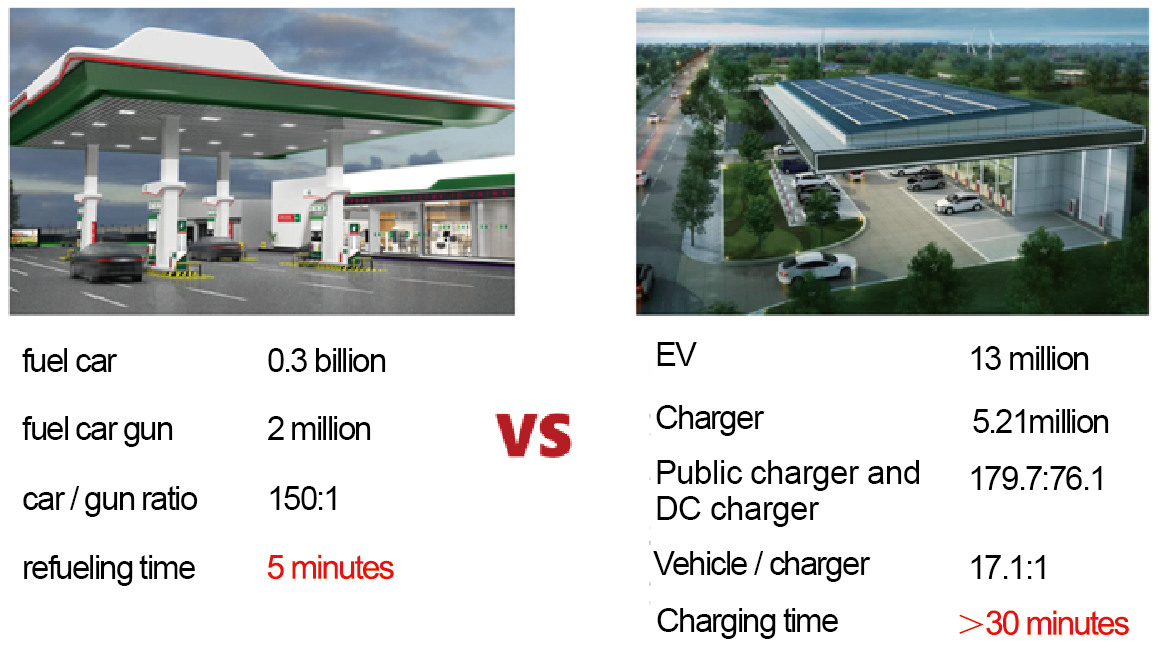

As of the end of 2022, there will be more than 300 million fuel passenger vehicles in the country, supporting 110,000 gas stations with about 2 million refueling guns, and the vehicle-to-gun ratio is 150:1; in contrast, there are currently about 1,300 electric passenger vehicles in my country. There are 5.21 million charging piles, of which 761,000 are public DC charging piles, and the ratio of vehicles to fast charging piles is 17.1:1. Each electric vehicle has much more public fast charging pile than fuel vehicles. Even so, electric vehicle owners dare not drive long distances, because the refueling time of fuel vehicles is about 5 minutes, and the fast charging of new mainstream electric vehicles requires at least half an hour to one hour.

The key to solving the problem of queuing at fast charging stations is to achieve 5-minute charging, that is, to use high-power liquid-cooled super charging.

Domestic mainstream car companies have launched or will soon launch supercharged vehicles that support 800V platforms, realizing the experience of adding 200 kilometers of battery life after charging at 480kW within 5 minutes. However, most of the existing liquid-cooled supercharging piles use liquid-cooled charging guns on the basis of traditional air-cooled charging piles to achieve a maximum charging output of 600A. We call them semi-liquid-cooled supercharging piles for the time being. The power part of the semi-liquid-cooled overcharging pile is forced air-cooled heat dissipation. As the charging power increases, the noise also increases. At the same time, because the air flows through the pile body, the reliability of the charging pile is difficult to guarantee, and the later maintenance costs are higher. Corresponding to it is the full liquid-cooled supercharging pile, which uses a liquid-cooled charging module and a liquid-cooled charging gun. The overall system adopts a liquid-cooled heat dissipation design, which has the characteristics of large charging current, low noise and high reliability. The full liquid-cooled overcharging system is the development direction of liquid-cooled overcharging in the future.

02 Advantages of full liquid cooling charging

Advantage 1: High current

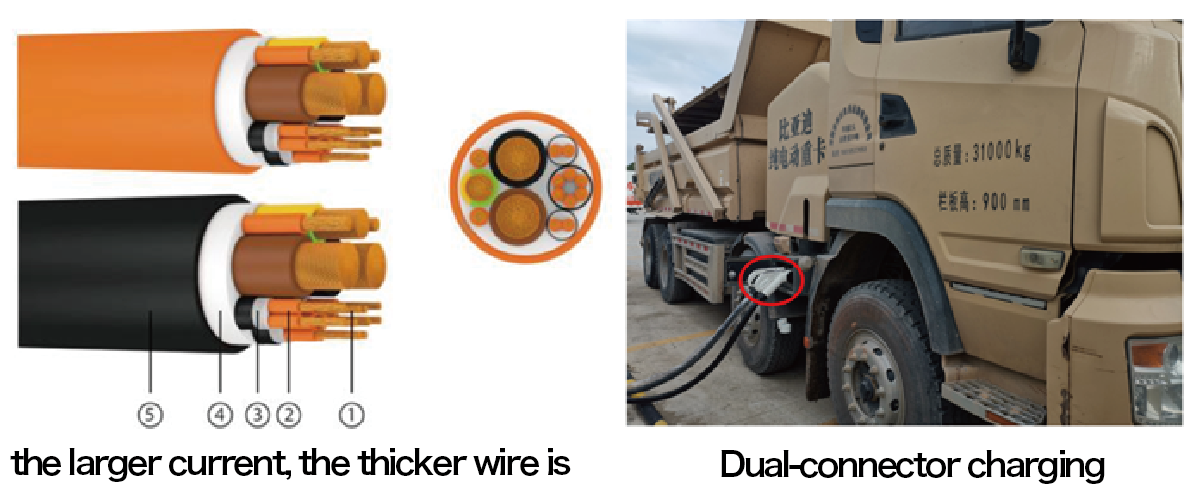

The output current of the charging pile is limited by the charging gun cable. The charging gun conducts electricity by the copper cable inside the gun wire, and the heating of the cable is proportional to the square value of the current. The larger the charging current, the greater the heating of the cable is. To reduce the heat generation of the cable and avoid overheating, the cross-sectional area of the wire must be increased, and of course the gun wire will be heavier. The current 250A national standard charging gun generally uses an 80mm 2 cable, and the overall charging gun is heavy and not easy to bend. If you want to achieve higher current charging, you can also use dual charging guns, but this is only an expedient measure for specific occasions. The ultimate solution for high current charging can only be charging with liquid-cooled charging guns.

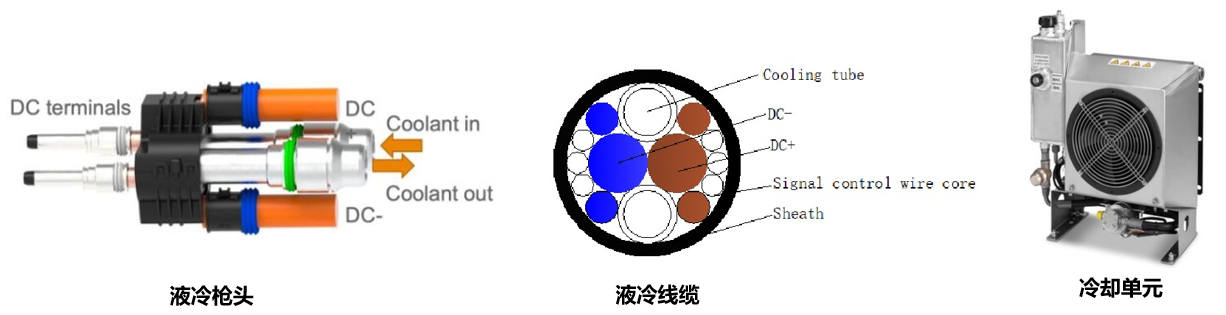

There are cables and water pipes inside the liquid-cooled charging gun. The cable of the 500A liquid-cooled charging gun is usually only 35mm2 , and the cooling liquid in the water pipe flows to remove heat. Because the cable is thin, the liquid-cooled charging gun is 30%~40% lighter than the conventional charging gun. The liquid-cooled charging gun also needs to be equipped with a cooling unit, which consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to circulate in the gun line, bringing the heat to the radiator, and then blown away by the fan, so as to achieve a larger carrying capacity than conventional natural cooling charging guns.

Advantage 2: High reliability

The reliability of the charging pile depends largely on the reliability of the charging module, that is, it is greatly affected by the external environment of operation.

The key to solving the problem of queuing at fast charging stations is to achieve 5-minute charging, that is, to use high-power liquid-cooled super charging.

Domestic mainstream car companies have launched or will soon launch supercharged vehicles that support 800V platforms, realizing the experience of adding 200 kilometers of battery life after charging at 480kW within 5 minutes. However, most of the existing liquid-cooled supercharging piles use liquid-cooled charging guns on the basis of traditional air-cooled charging piles to achieve a maximum charging output of 600A. We call them semi-liquid-cooled supercharging piles for the time being. The power part of the semi-liquid-cooled overcharging pile is forced air-cooled heat dissipation. As the charging power increases, the noise also increases. At the same time, because the air flows through the pile body, the reliability of the charging pile is difficult to guarantee, and the later maintenance costs are higher. Corresponding to it is the full liquid-cooled supercharging pile, which uses a liquid-cooled charging module and a liquid-cooled charging gun. The overall system adopts a liquid-cooled heat dissipation design, which has the characteristics of large charging current, low noise and high reliability. The full liquid-cooled overcharging system is the development direction of liquid-cooled overcharging in the future.

02 Advantages of full liquid cooling charging

Advantage 1: High current

The output current of the charging pile is limited by the charging gun cable. The charging gun conducts electricity by the copper cable inside the gun wire, and the heating of the cable is proportional to the square value of the current. The larger the charging current, the greater the heating of the cable is. To reduce the heat generation of the cable and avoid overheating, the cross-sectional area of the wire must be increased, and of course the gun wire will be heavier. The current 250A national standard charging gun generally uses an 80mm 2 cable, and the overall charging gun is heavy and not easy to bend. If you want to achieve higher current charging, you can also use dual charging guns, but this is only an expedient measure for specific occasions. The ultimate solution for high current charging can only be charging with liquid-cooled charging guns.

There are cables and water pipes inside the liquid-cooled charging gun. The cable of the 500A liquid-cooled charging gun is usually only 35mm2 , and the cooling liquid in the water pipe flows to remove heat. Because the cable is thin, the liquid-cooled charging gun is 30%~40% lighter than the conventional charging gun. The liquid-cooled charging gun also needs to be equipped with a cooling unit, which consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to circulate in the gun line, bringing the heat to the radiator, and then blown away by the fan, so as to achieve a larger carrying capacity than conventional natural cooling charging guns.

Advantage 2: High reliability

The reliability of the charging pile depends largely on the reliability of the charging module, that is, it is greatly affected by the external environment of operation.

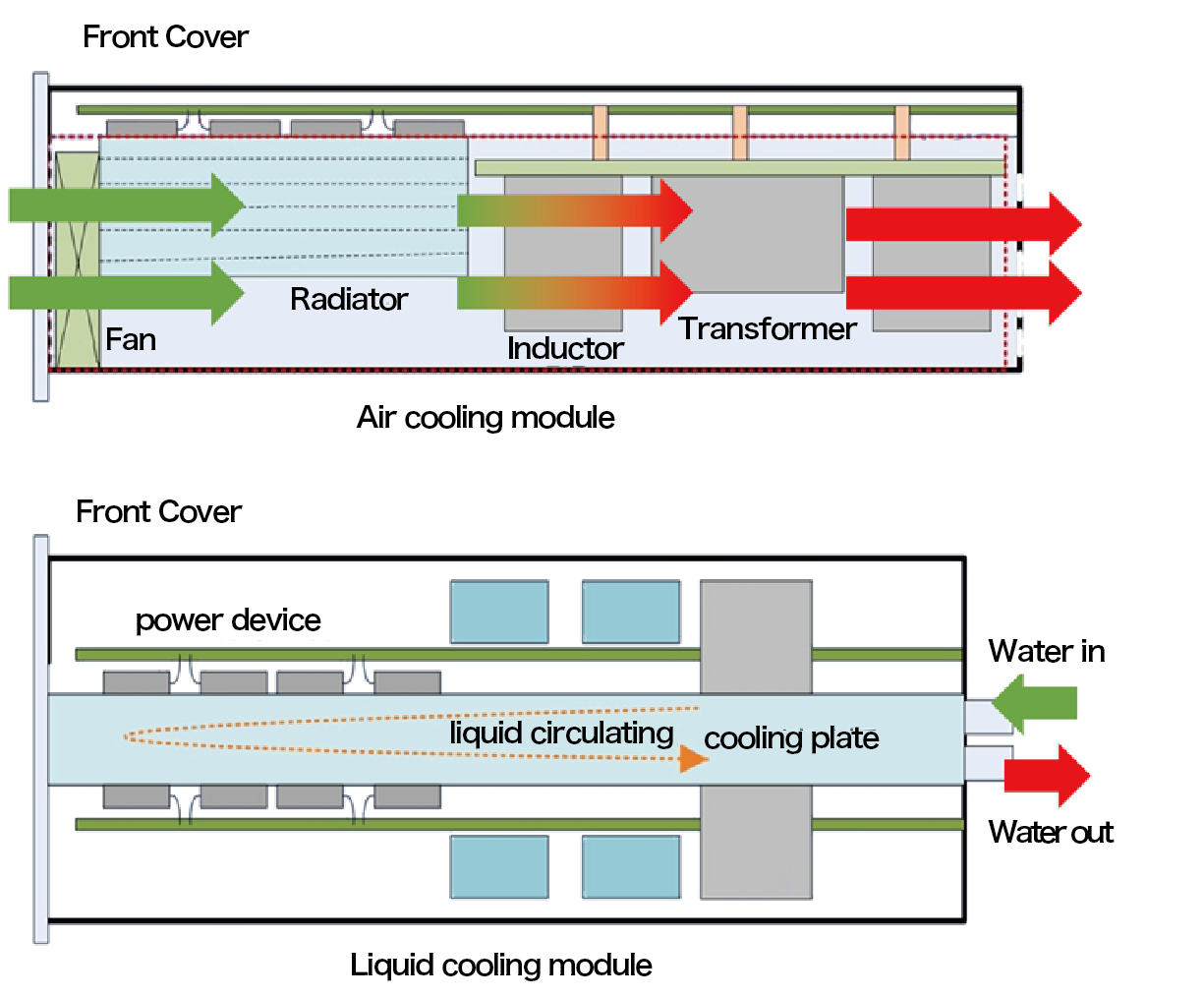

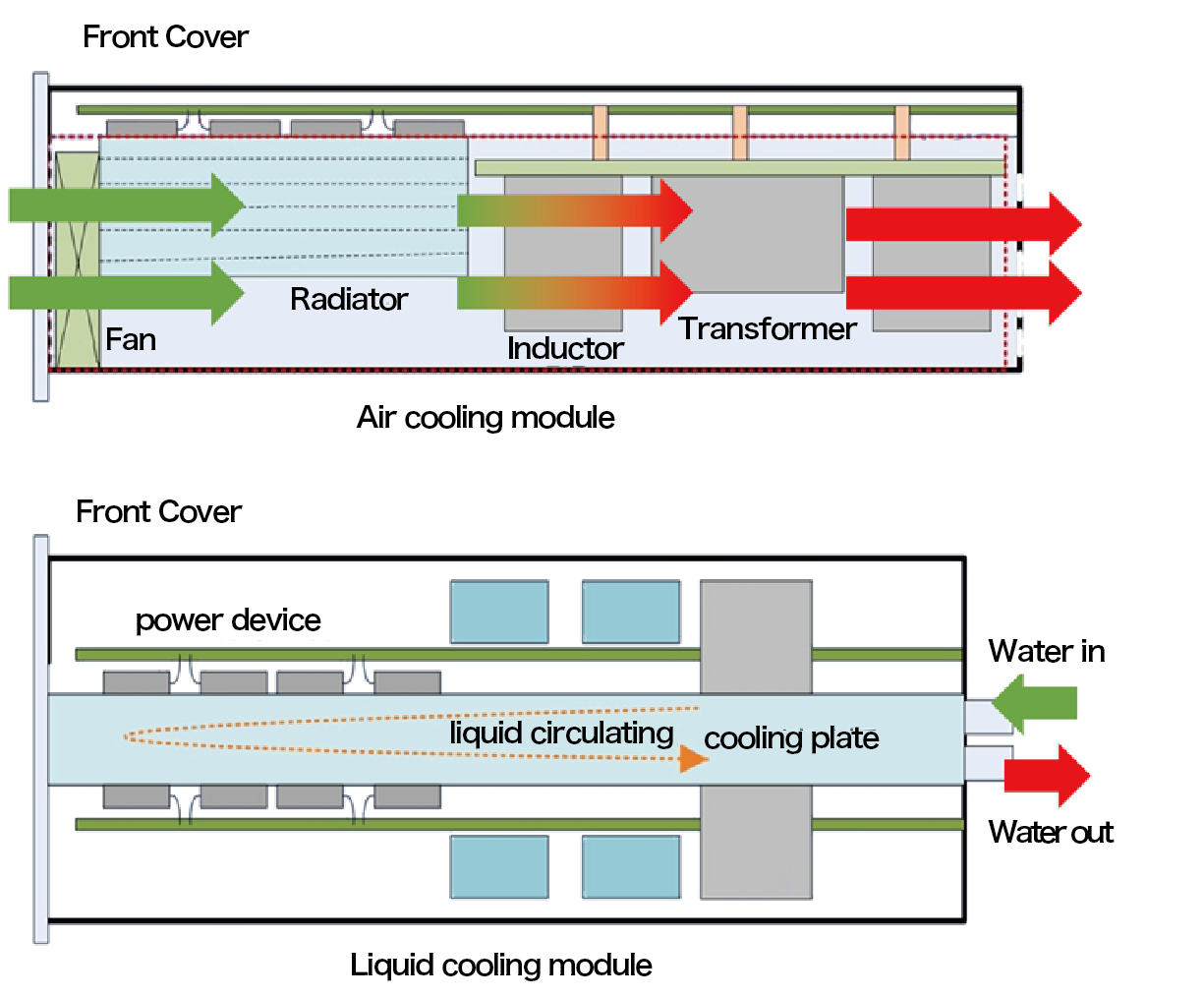

The cabinet of conventional charging piles and semi-liquid-cooled charging piles are air-cooled and dissipated. The air will be mixed with dust, salt mist and water vapor and adsorbed on the surface of internal devices, resulting in poor system insulation, poor heat dissipation, low charging efficiency, and reduced equipment life. For conventional charging piles or semi-liquid-cooled charging piles, heat dissipation and protection are two contradictory concepts. If the protection is good, the heat dissipation is difficult to design, and if the heat dissipation is good, the protection is difficult to handle.

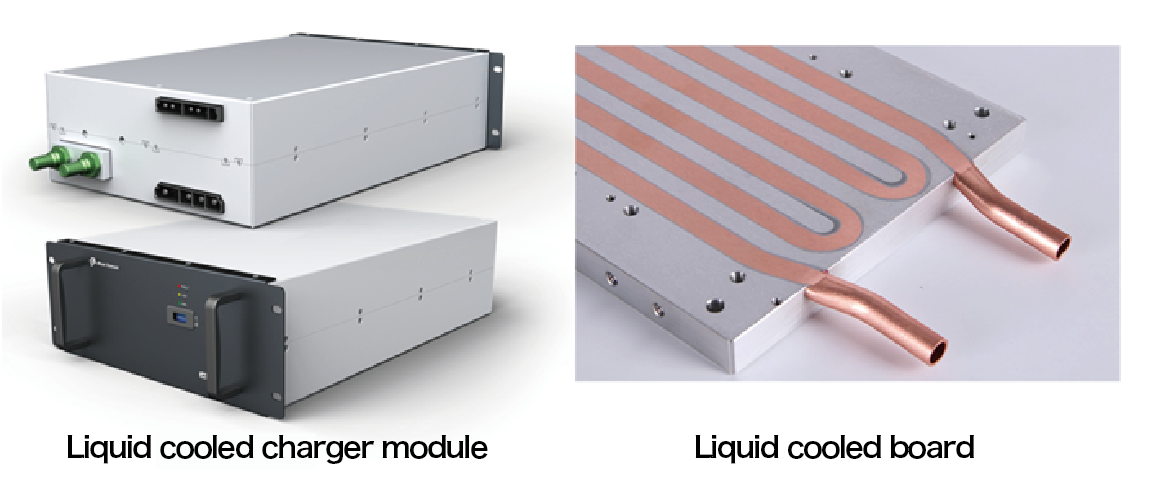

The full liquid-cooled charging pile adopts a liquid-cooled charging module. There is no air duct on the front and back of the liquid-cooled module. The module relies on the cooling fluid circulated inside the liquid-cooled plate to exchange heat with the outside world, so that the power part of the charging pile can be fully enclosed to reduce heat dissipation. The radiator is external, and the heat is brought to the radiator through the coolant inside, and the external air blows away the heat on the surface of the radiator. The liquid-cooled charging module and electrical accessories in the charging pile have no contact with the external environment, so that IP65 protection can be achieved and the reliability is higher.

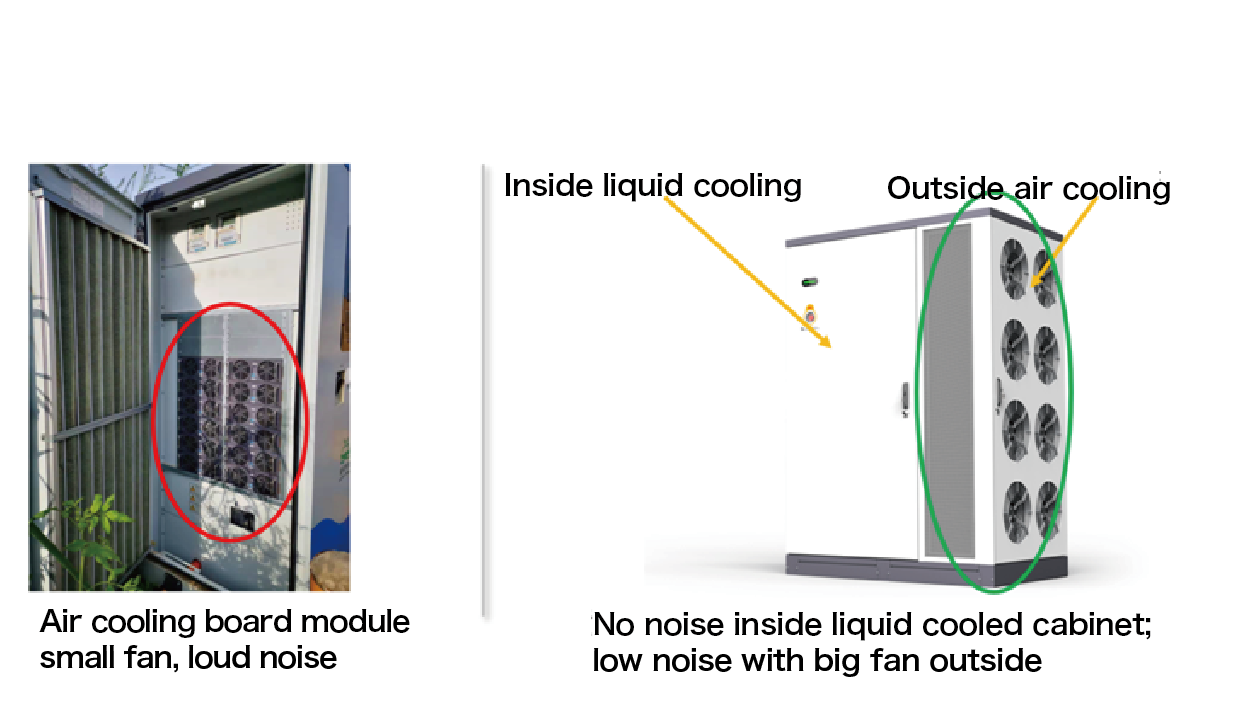

Advantage three: low noise

Conventional charging piles and semi-liquid-cooled charging piles have built-in air-cooled charging modules. The air-cooled modules have built-in multiple high-speed small fans, and the operating noise can reach above 65db. The noise is basically above 70dB when running at full power, which has little impact during the day, but is very disturbing at night. Therefore, the loud noise of the charging station is the most complained problem of the operators, and they have to rectify it if they are complained. However, the rectification cost is high and the effect is very limited. In the end, they have to reduce the power to reduce the noise.

The fully liquid-cooled charging pile adopts a dual-circulation heat dissipation structure. The internal liquid-cooled module relies on a water pump to drive the coolant to circulate heat, and transfers the heat generated by the module to the finned radiator. The heat dissipates from the device, and the noise of the fan with low speed and large air volume is much lower than that of the small fan with higher speed. The full liquid-cooled supercharging pile can also adopt a split-type heat dissipation design, which is similar to a split-type air conditioner. The heat dissipation unit is placed away from the crowd, and it can even exchange heat with pools and fountains to achieve better heat dissipation and lower temperature. noise.

Advantage 4: Low TCO

The cost of charging equipment at the charging station must be considered from the total life cycle cost (TCO) of the charging pile. The life of the traditional charging pile with air-cooled charging modules generally does not exceed 5 years, but the current lease period of the charging station operation is 8-10 years, which means that the charging equipment needs to be replaced at least once during the operation cycle of the station. In contrast, the service life of full liquid-cooled charging piles is at least 10 years, which can cover the entire life cycle of the station. At the same time, compared with the charging pile using the air-cooled module, which requires frequent operations such as opening the cabinet for dust removal and maintenance, the full liquid-cooled charging pile only needs to be washed after the external radiator has accumulated dust, and the maintenance is simple.

The TCO of the full liquid cooling charging system is lower than that of the traditional charging system using air-cooling charging modules, and with the wide application of the full liquid cooling system in batches, its cost-effective advantage will become more obvious.

03 The principle of full liquid cooling charging

The full liquid-cooled charging system uses a liquid-cooled charging module and a liquid-cooled charging gun, and the system as a whole uses liquid-cooled heat dissipation. As shown in the figure, the working principle of the integrated fully liquid-cooled charging system, the liquid-cooled charging gun and the liquid-cooled charging module share a cold source. The liquid cooling system consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to flow between the liquid cooling plate and the liquid cooling gun line of the liquid cooling module, bringing the heat to the radiator, and then blowing it away through a large air volume fan. After cooling down, the coolant returns to the water tank and circulates heat through the water pump repeatedly.

The power part of the system adopts liquid cooling to dissipate heat, and there is no air exchange with the external environment, so the design of IP65 can be realized. At the same time, the system uses a large air volume fan to dissipate heat with low noise and high environmental friendliness.

04 Infypower Source Technology - Liquid Cooled Charging Products

Infypower is the earliest enterprise in China that is committed to the development and actual batch application of liquid-cooled power conversion modules and full liquid-cooled charging systems.

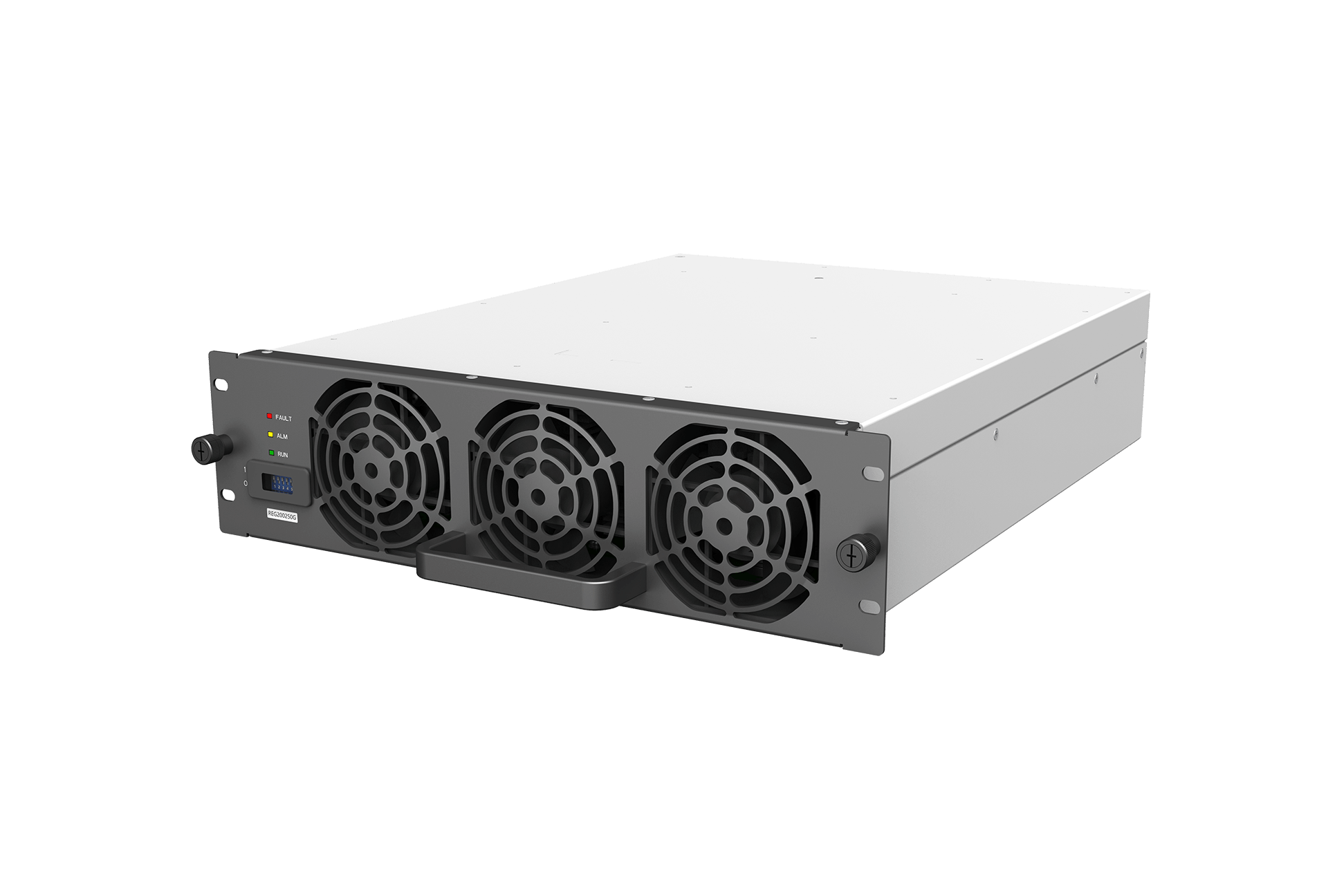

Liquid Cooling Module

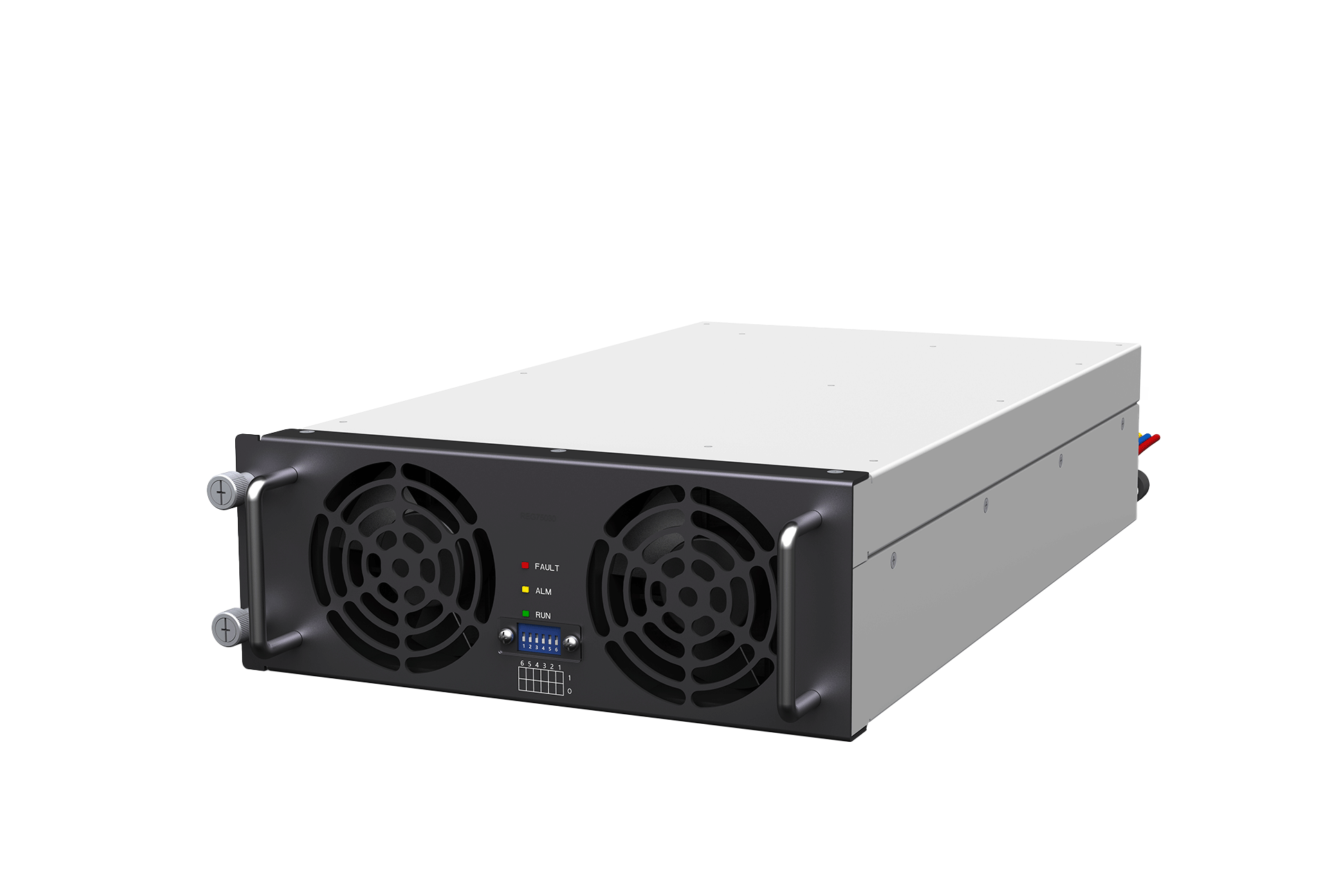

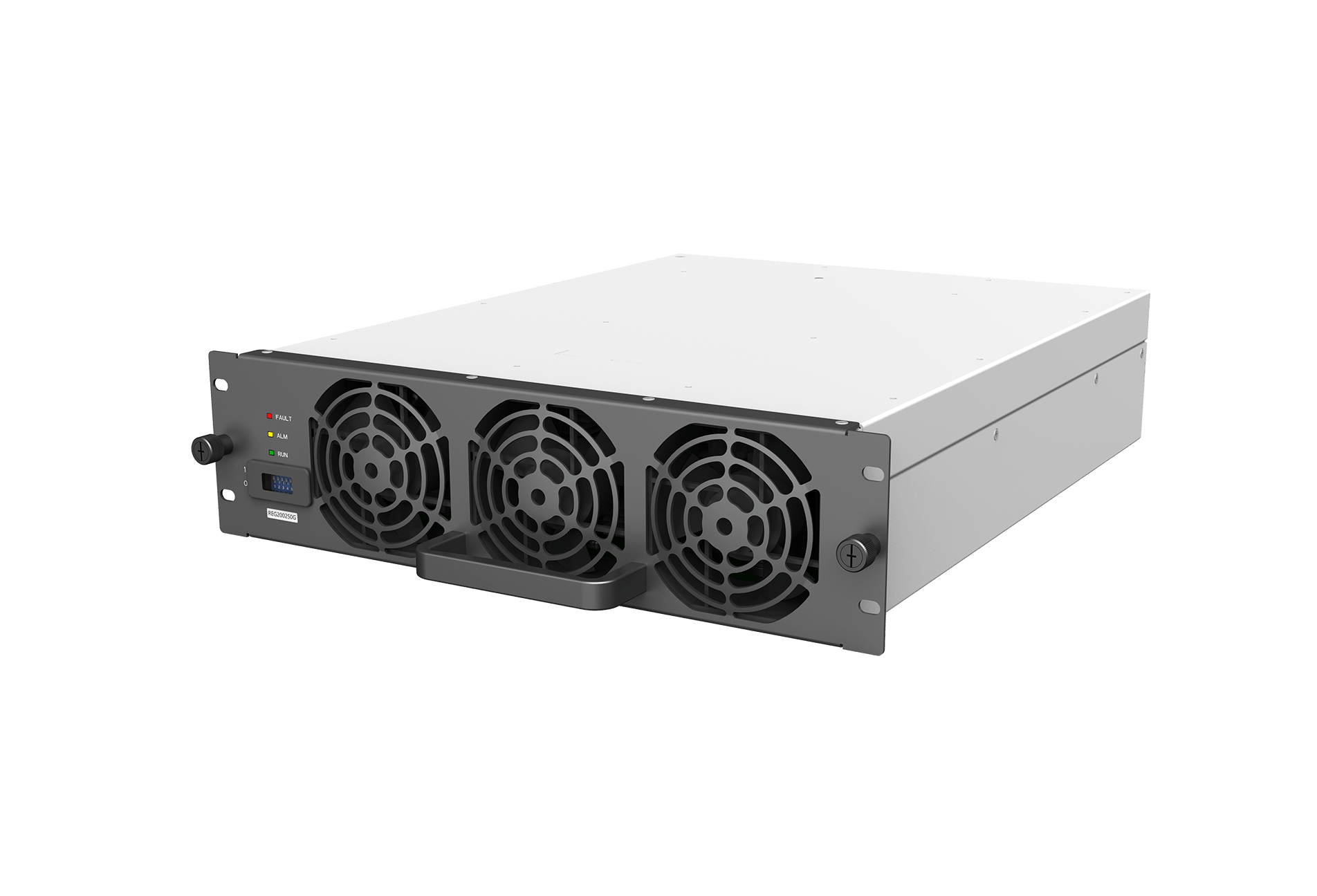

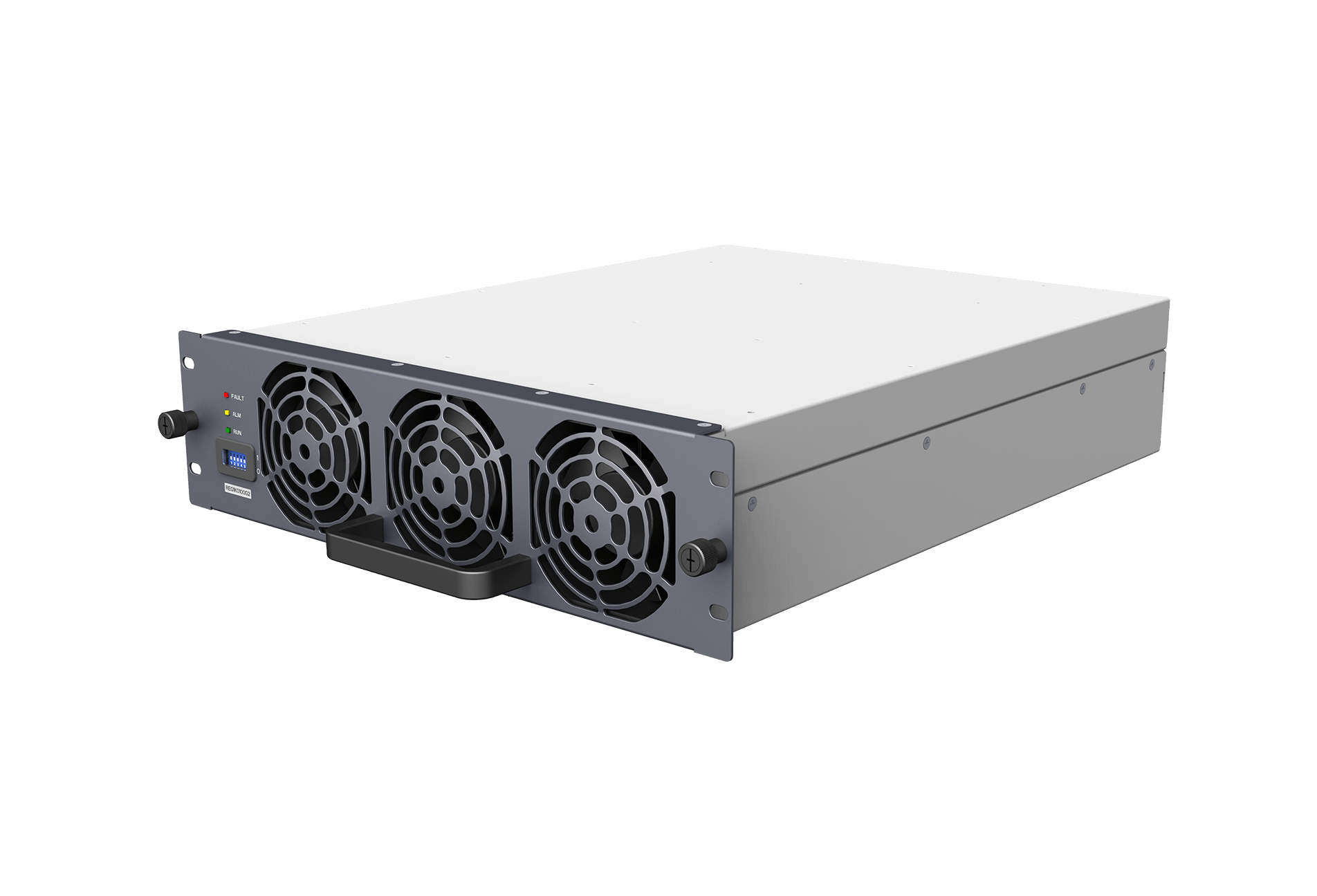

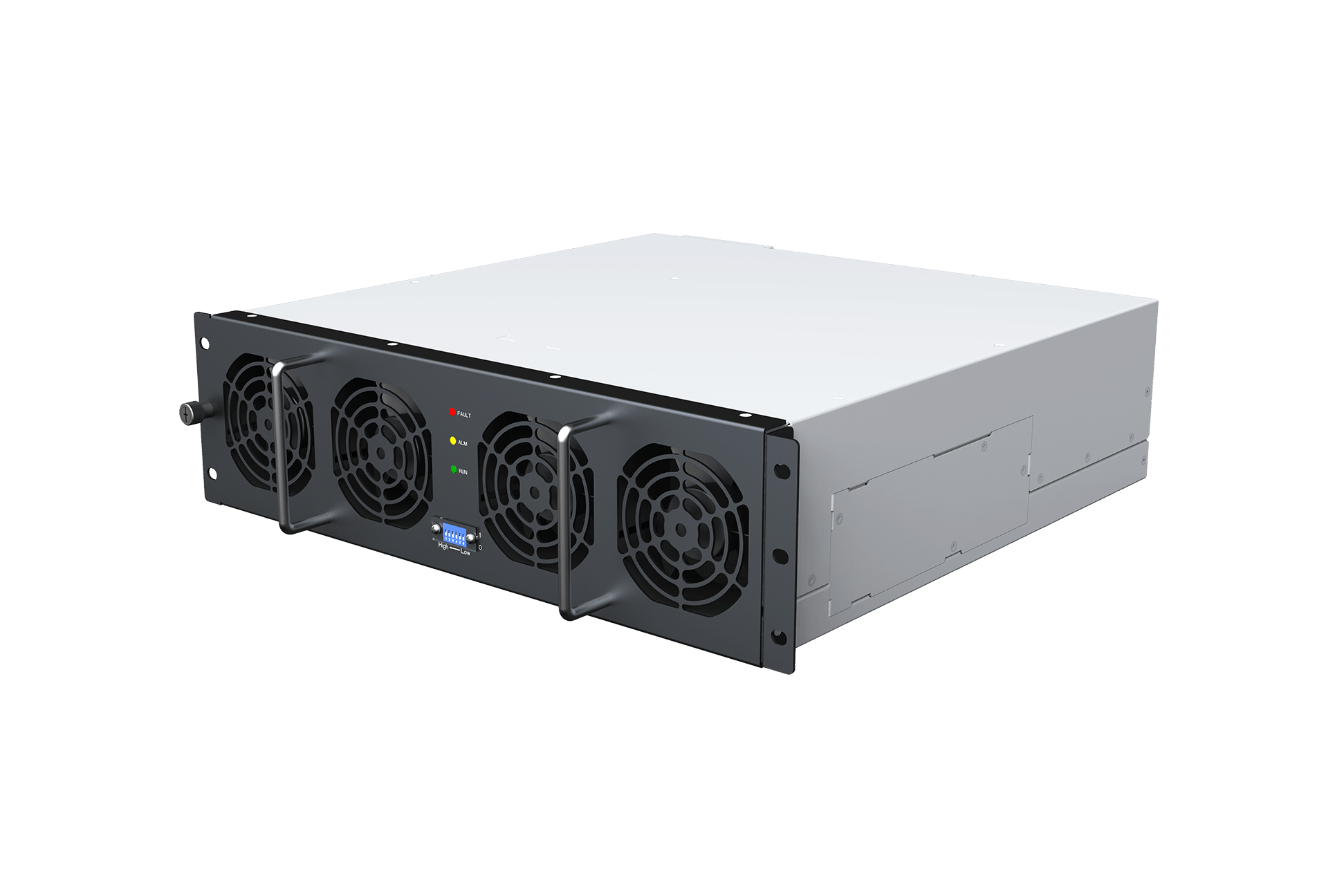

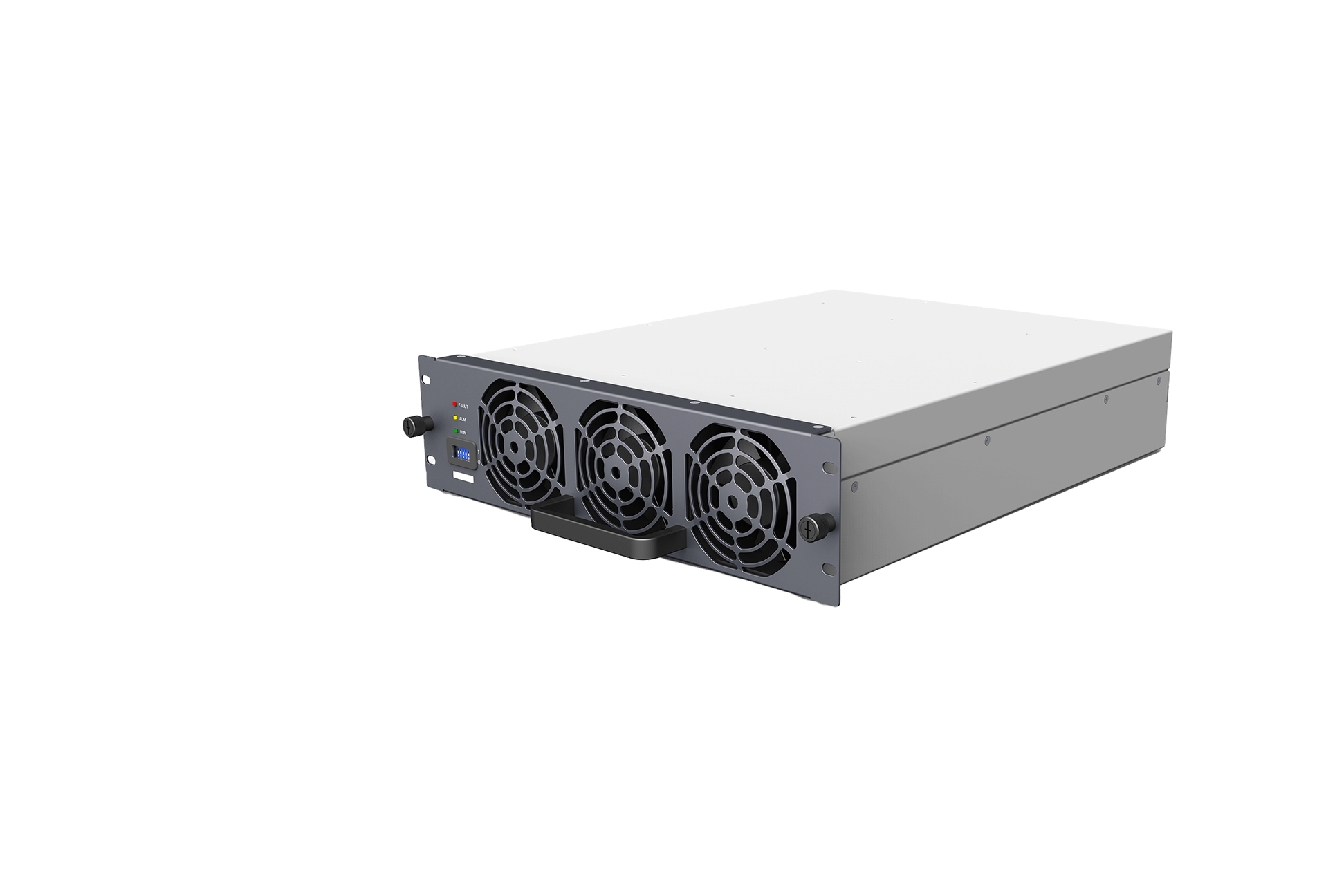

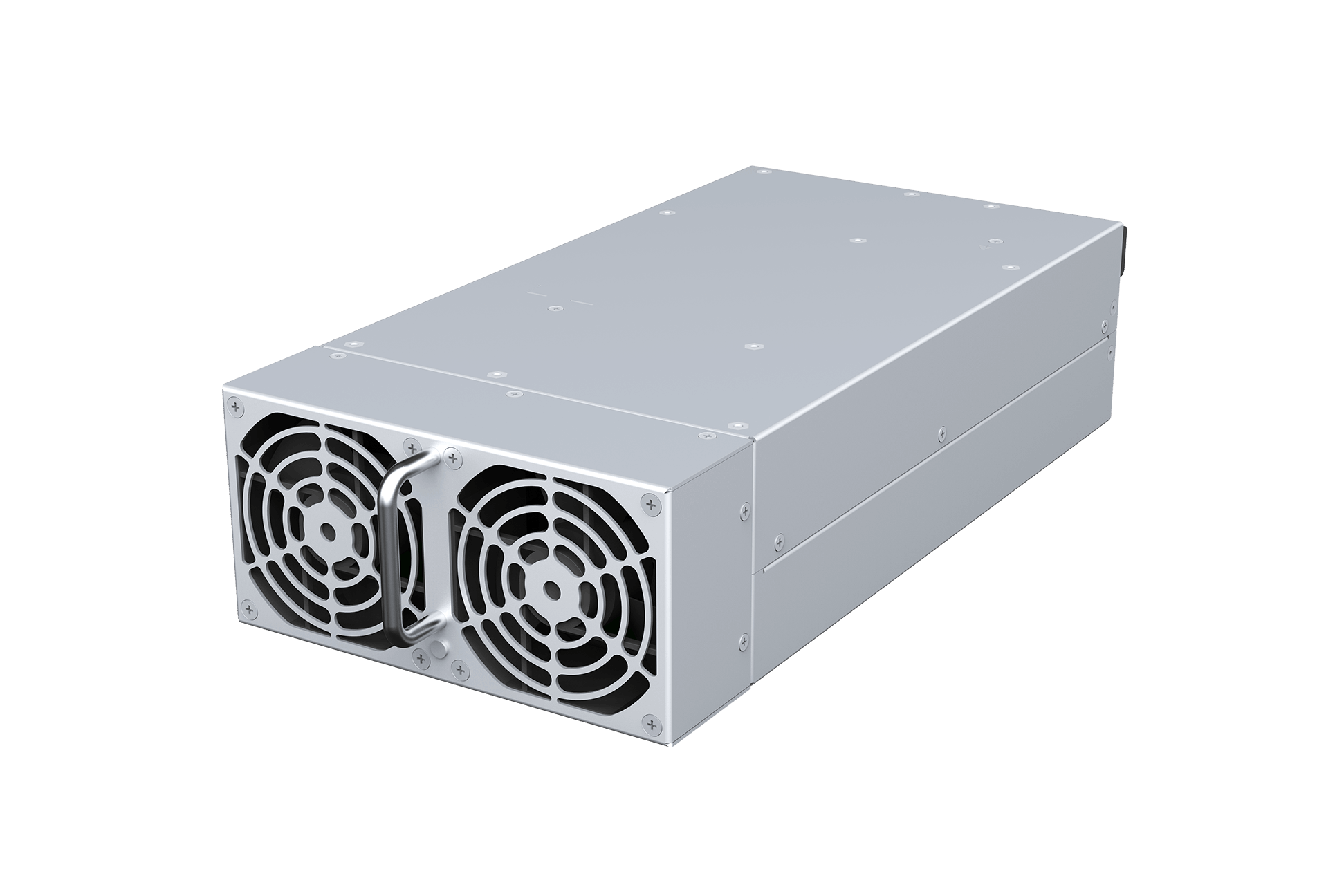

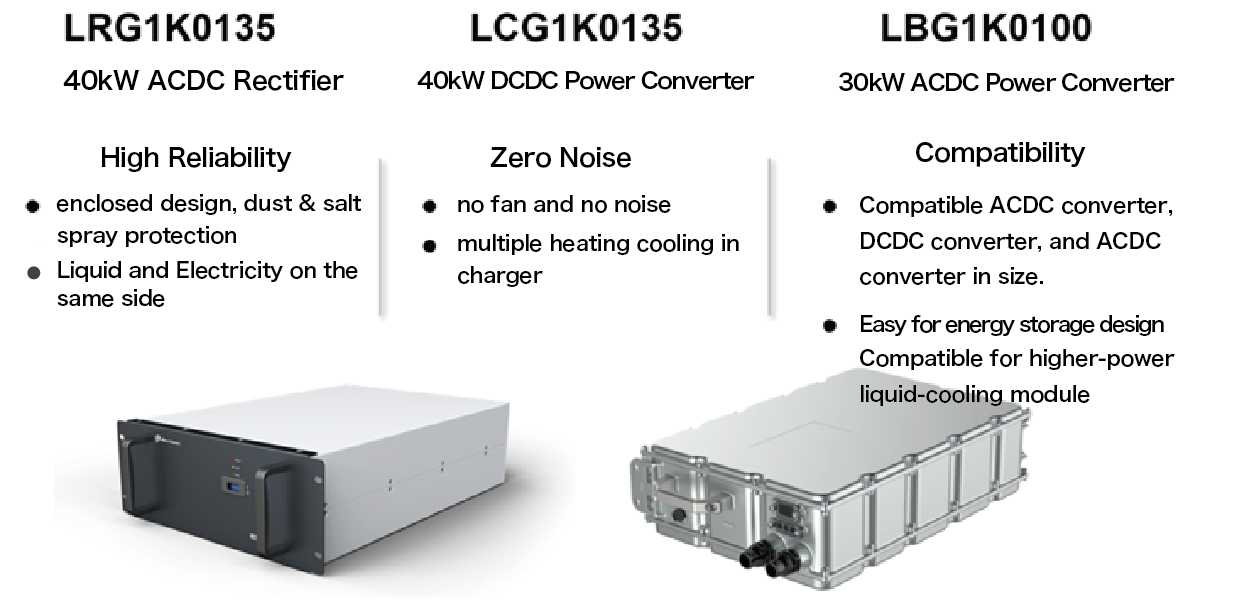

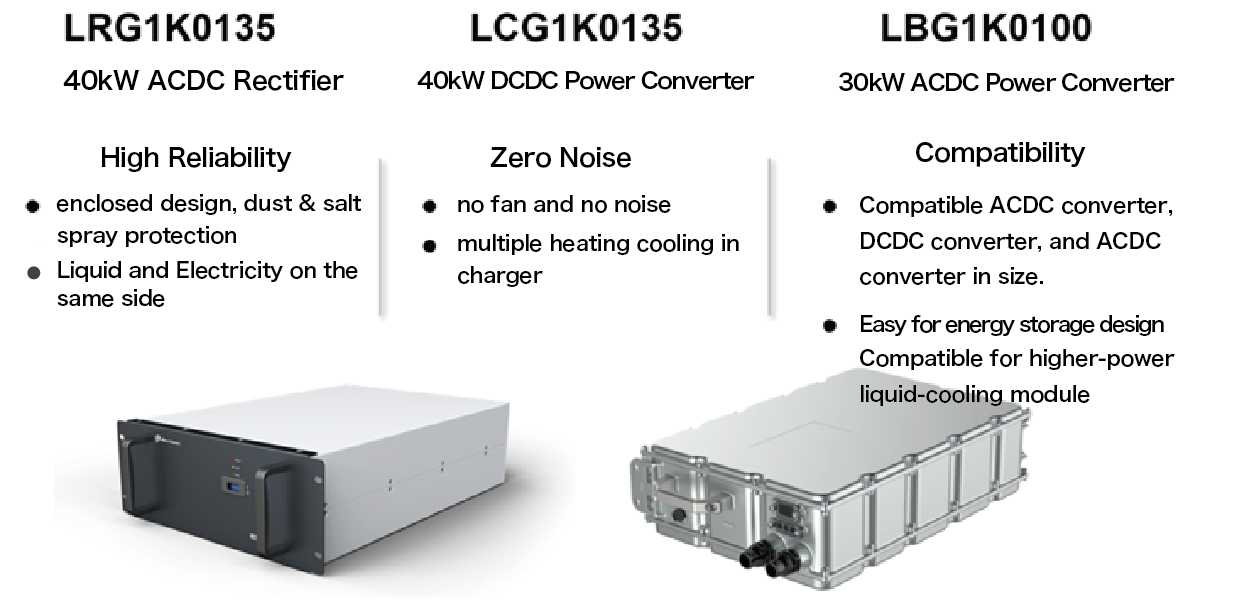

After several generations of liquid cooling module product iterations and technology accumulation, the current source liquid cooling power conversion modules cover three series of LRG series charging modules, LCG series DCDC DC conversion modules, and LBG series ACDC bidirectional conversion modules, which can meet the requirements of liquid cooling.

The cabinet of conventional charging piles and semi-liquid-cooled charging piles are air-cooled and dissipated. The air will be mixed with dust, salt mist and water vapor and adsorbed on the surface of internal devices, resulting in poor system insulation, poor heat dissipation, low charging efficiency, and reduced equipment life. For conventional charging piles or semi-liquid-cooled charging piles, heat dissipation and protection are two contradictory concepts. If the protection is good, the heat dissipation is difficult to design, and if the heat dissipation is good, the protection is difficult to handle.

The full liquid-cooled charging pile adopts a liquid-cooled charging module. There is no air duct on the front and back of the liquid-cooled module. The module relies on the cooling fluid circulated inside the liquid-cooled plate to exchange heat with the outside world, so that the power part of the charging pile can be fully enclosed to reduce heat dissipation. The radiator is external, and the heat is brought to the radiator through the coolant inside, and the external air blows away the heat on the surface of the radiator. The liquid-cooled charging module and electrical accessories in the charging pile have no contact with the external environment, so that IP65 protection can be achieved and the reliability is higher.

Advantage three: low noise

Conventional charging piles and semi-liquid-cooled charging piles have built-in air-cooled charging modules. The air-cooled modules have built-in multiple high-speed small fans, and the operating noise can reach above 65db. The noise is basically above 70dB when running at full power, which has little impact during the day, but is very disturbing at night. Therefore, the loud noise of the charging station is the most complained problem of the operators, and they have to rectify it if they are complained. However, the rectification cost is high and the effect is very limited. In the end, they have to reduce the power to reduce the noise.

The fully liquid-cooled charging pile adopts a dual-circulation heat dissipation structure. The internal liquid-cooled module relies on a water pump to drive the coolant to circulate heat, and transfers the heat generated by the module to the finned radiator. The heat dissipates from the device, and the noise of the fan with low speed and large air volume is much lower than that of the small fan with higher speed. The full liquid-cooled supercharging pile can also adopt a split-type heat dissipation design, which is similar to a split-type air conditioner. The heat dissipation unit is placed away from the crowd, and it can even exchange heat with pools and fountains to achieve better heat dissipation and lower temperature. noise.

Advantage 4: Low TCO

The cost of charging equipment at the charging station must be considered from the total life cycle cost (TCO) of the charging pile. The life of the traditional charging pile with air-cooled charging modules generally does not exceed 5 years, but the current lease period of the charging station operation is 8-10 years, which means that the charging equipment needs to be replaced at least once during the operation cycle of the station. In contrast, the service life of full liquid-cooled charging piles is at least 10 years, which can cover the entire life cycle of the station. At the same time, compared with the charging pile using the air-cooled module, which requires frequent operations such as opening the cabinet for dust removal and maintenance, the full liquid-cooled charging pile only needs to be washed after the external radiator has accumulated dust, and the maintenance is simple.

The TCO of the full liquid cooling charging system is lower than that of the traditional charging system using air-cooling charging modules, and with the wide application of the full liquid cooling system in batches, its cost-effective advantage will become more obvious.

03 The principle of full liquid cooling charging

The full liquid-cooled charging system uses a liquid-cooled charging module and a liquid-cooled charging gun, and the system as a whole uses liquid-cooled heat dissipation. As shown in the figure, the working principle of the integrated fully liquid-cooled charging system, the liquid-cooled charging gun and the liquid-cooled charging module share a cold source. The liquid cooling system consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to flow between the liquid cooling plate and the liquid cooling gun line of the liquid cooling module, bringing the heat to the radiator, and then blowing it away through a large air volume fan. After cooling down, the coolant returns to the water tank and circulates heat through the water pump repeatedly.

The power part of the system adopts liquid cooling to dissipate heat, and there is no air exchange with the external environment, so the design of IP65 can be realized. At the same time, the system uses a large air volume fan to dissipate heat with low noise and high environmental friendliness.

04 Infypower Source Technology - Liquid Cooled Charging Products

Infypower is the earliest enterprise in China that is committed to the development and actual batch application of liquid-cooled power conversion modules and full liquid-cooled charging systems.

Liquid Cooling Module

After several generations of liquid cooling module product iterations and technology accumulation, the current source liquid cooling power conversion modules cover three series of LRG series charging modules, LCG series DCDC DC conversion modules, and LBG series ACDC bidirectional conversion modules, which can meet the requirements of liquid cooling.

The liquid-cooled power conversion module has the advantages of low noise and high reliability. Infypower also unifies the size and interface design of the charging module, DCDC conversion module, and ACDC bidirectional module of the same power level, so that it can be used in overcharging systems, storage and charging. During the design process of the system, a unified structure and heat dissipation design can be carried out. In specific applications, the charging module or storage and charging module can be configured according to the actual situation to achieve high compatibility of system design.

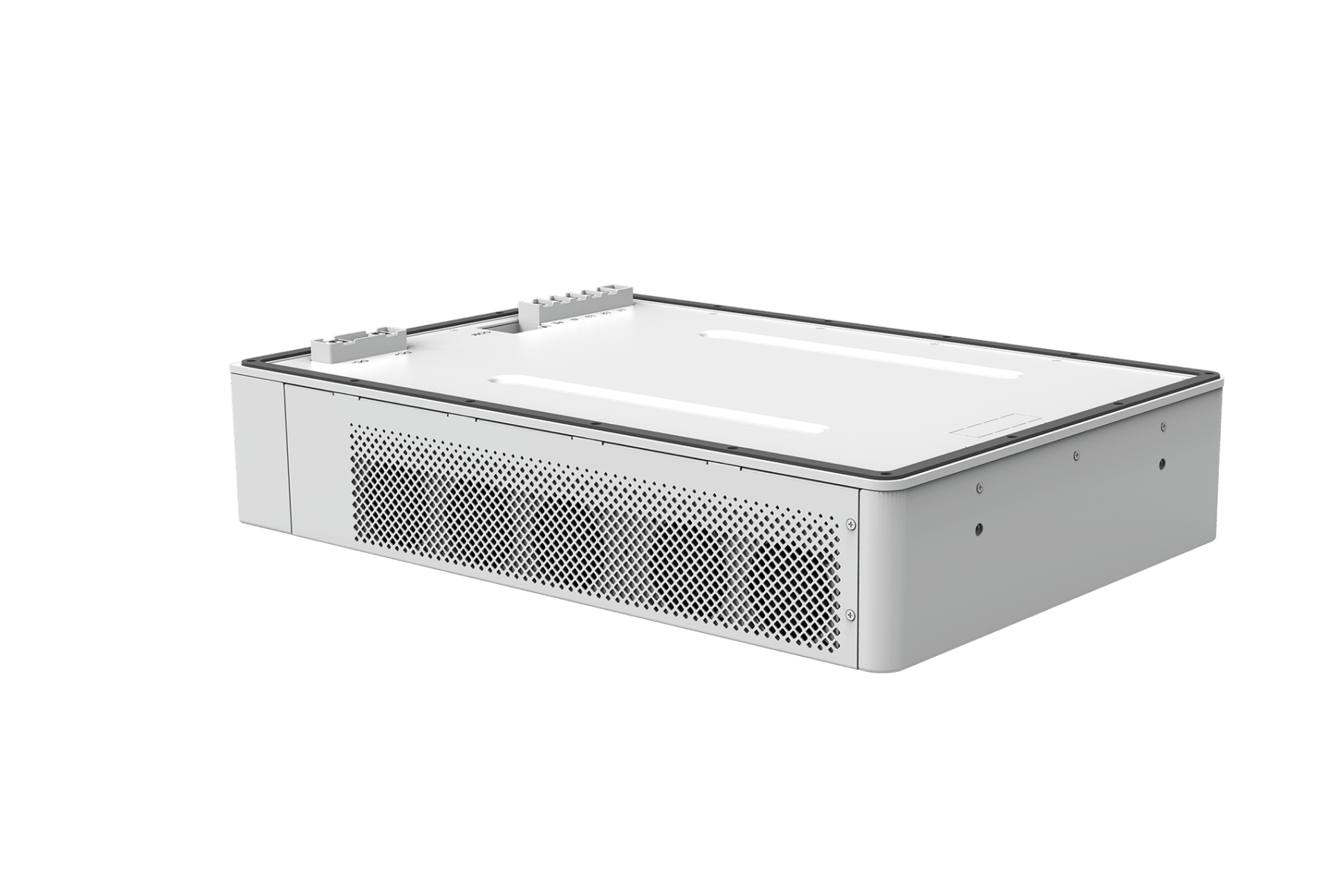

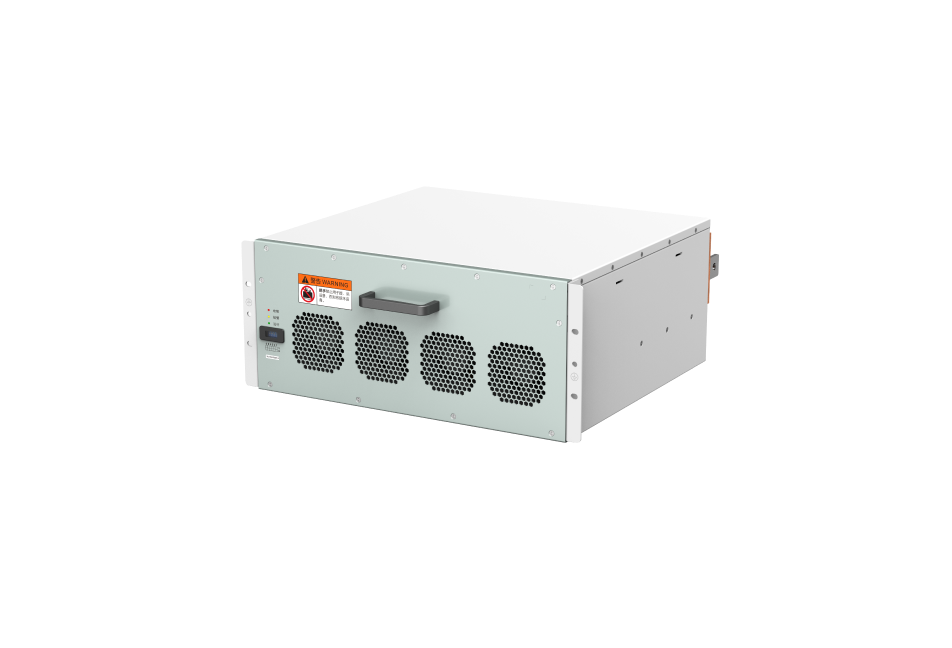

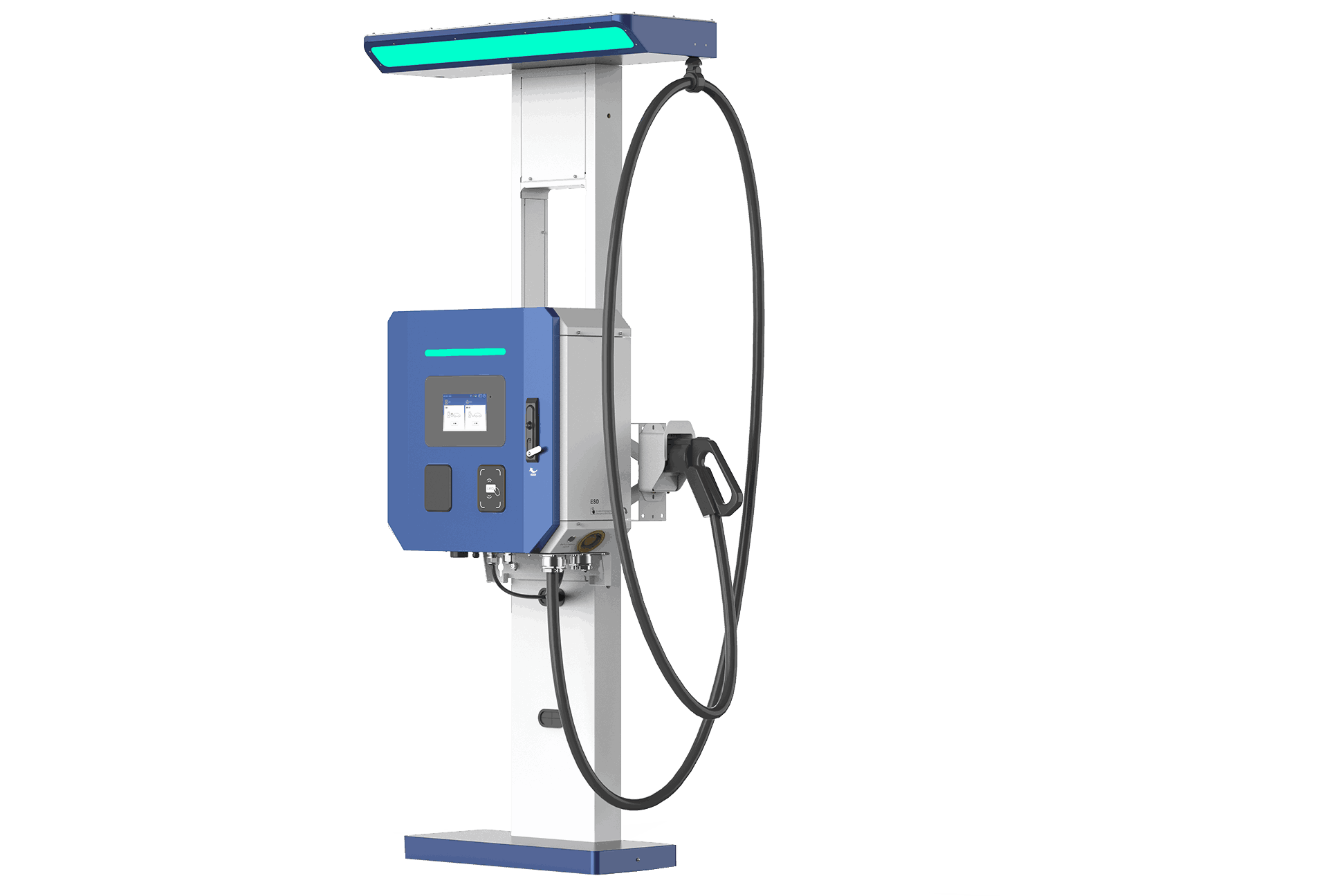

Liquid Cooled Overcharge System

For medium-power fast charging applications, Infypower has launched an integrated 240kW full liquid-cooled fast charging system as shown in the figure. The system is equipped with six 40kW liquid-cooled charging modules, a 250A conventional charging gun and a 500A liquid-cooled charging module. charging gun. The liquid-cooled output port can achieve a full power output of 240kW, and can charge a passenger car (Tesla, Jikrypton, etc.) on a 400V platform at a maximum of 500A. At the same time, the system has extremely low noise, high reliability, and light gun wires, and can be widely used in high-end charging places such as residential areas, office areas, and brand charging stations.

The liquid-cooled power conversion module has the advantages of low noise and high reliability. Infypower also unifies the size and interface design of the charging module, DCDC conversion module, and ACDC bidirectional module of the same power level, so that it can be used in overcharging systems, storage and charging. During the design process of the system, a unified structure and heat dissipation design can be carried out. In specific applications, the charging module or storage and charging module can be configured according to the actual situation to achieve high compatibility of system design.

Liquid Cooled Overcharge System

For medium-power fast charging applications, Infypower has launched an integrated 240kW full liquid-cooled fast charging system as shown in the figure. The system is equipped with six 40kW liquid-cooled charging modules, a 250A conventional charging gun and a 500A liquid-cooled charging module. charging gun. The liquid-cooled output port can achieve a full power output of 240kW, and can charge a passenger car (Tesla, Jikrypton, etc.) on a 400V platform at a maximum of 500A. At the same time, the system has extremely low noise, high reliability, and light gun wires, and can be widely used in high-end charging places such as residential areas, office areas, and brand charging stations.

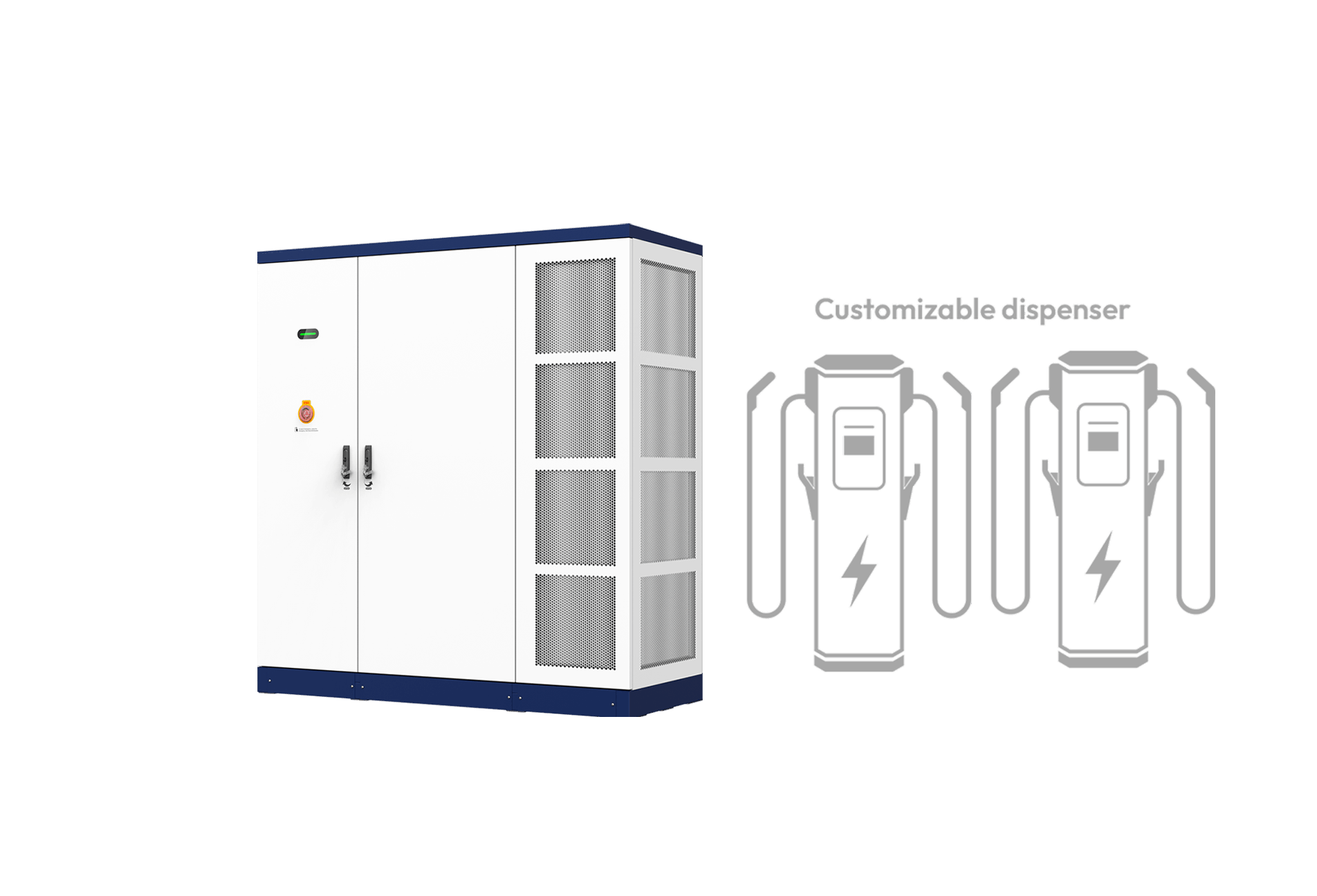

For high-power overcharging applications, Infypower has launched a 640kW split-type fully liquid-cooled overcharging system as shown in the figure below. The system adopts a split-type design and consists of a liquid-cooled power cabinet and a liquid-cooled charging terminal. The side of the liquid-cooled power supply cabinet dissipates heat, and the protection level of the power part can reach IP65; the power is dynamically distributed among the liquid-cooled charging terminals, and a single gun can achieve a maximum power output of 480kW, which can increase the mileage of 200+ kilometers after charging for 5 minutes. The system has the advantages of low noise, high reliability, and simple maintenance. It can be widely used in various super charging stations and brand charging stations to provide car owners with a high-quality charging experience.

Liquid cooling storage and charging system

Liquid-cooled overcharging is the development direction of high-power charging, but the batch deployment of overcharging is facing the problem of insufficient power distribution capacity. The power distribution capacity required by an overcharging system is equivalent to the power capacity required by a residential building. The power distribution demand of the overcharging site is equivalent to the power demand of a residential area. The best solution to solve the problem of insufficient power distribution capacity at overcharging sites is to increase energy storage facilities, that is, liquid-cooled energy storage and charging. In view of this, Infypower has launched an 800kW full liquid-cooled storage and charging system.

Infypower's liquid-cooled storage and charging system adopts an AC-DC hybrid bus architecture, the AC bus is connected to the power grid, and the DC bus is connected to the energy storage battery. The electrical connection between the energy storage battery and the overcharging system is the DC bus, and the DC bus can also be easily connected to the photovoltaic module through the DCDC module, and the energy conversion efficiency is 3%~4% higher than that of the conventional AC bus.

Infypower’s fully liquid-cooled storage and charging system adopts a modular design, and can configure energy storage/charging power, energy storage battery capacity, and the number of charging terminals according to actual scene requirements. The inside of the liquid-cooled power cabinet is divided into power distribution compartment, power compartment and heat dissipation compartment. Because the size and interface of various functional modules of the same power level are unified, the structure of the power compartment can be uniformly designed, and various modules can be flexibly configured in practical applications. Realize different configurations of energy storage and charging power; the electrical configuration of the power distribution warehouse can be designed and prefabricated according to the different functions and power requirements of light, storage, and charging, and can be flexibly combined on site. Therefore, this set of liquid-cooled overcharge system has extremely high compatibility and flexibility.

05 High reliability

The refueling charging experience has always been the expectation of the majority of electric car owners, car companies and operators. With the increasing maturity of battery technology, the era of 5-minute fast charging may come much sooner than we expected. Full liquid-cooled supercharging will also become the mainstream choice for supercharging stations due to its high reliability, environmental friendliness and low TCO operating costs. Infypower will continue to be committed to the research and development of core technologies and products for power conversion , and provide the industry with a full range of liquid-cooled power conversion modules and the best liquid-cooled overcharging system solutions.

For high-power overcharging applications, Infypower has launched a 640kW split-type fully liquid-cooled overcharging system as shown in the figure below. The system adopts a split-type design and consists of a liquid-cooled power cabinet and a liquid-cooled charging terminal. The side of the liquid-cooled power supply cabinet dissipates heat, and the protection level of the power part can reach IP65; the power is dynamically distributed among the liquid-cooled charging terminals, and a single gun can achieve a maximum power output of 480kW, which can increase the mileage of 200+ kilometers after charging for 5 minutes. The system has the advantages of low noise, high reliability, and simple maintenance. It can be widely used in various super charging stations and brand charging stations to provide car owners with a high-quality charging experience.

Liquid cooling storage and charging system

Liquid-cooled overcharging is the development direction of high-power charging, but the batch deployment of overcharging is facing the problem of insufficient power distribution capacity. The power distribution capacity required by an overcharging system is equivalent to the power capacity required by a residential building. The power distribution demand of the overcharging site is equivalent to the power demand of a residential area. The best solution to solve the problem of insufficient power distribution capacity at overcharging sites is to increase energy storage facilities, that is, liquid-cooled energy storage and charging. In view of this, Infypower has launched an 800kW full liquid-cooled storage and charging system.

Infypower's liquid-cooled storage and charging system adopts an AC-DC hybrid bus architecture, the AC bus is connected to the power grid, and the DC bus is connected to the energy storage battery. The electrical connection between the energy storage battery and the overcharging system is the DC bus, and the DC bus can also be easily connected to the photovoltaic module through the DCDC module, and the energy conversion efficiency is 3%~4% higher than that of the conventional AC bus.

Infypower’s fully liquid-cooled storage and charging system adopts a modular design, and can configure energy storage/charging power, energy storage battery capacity, and the number of charging terminals according to actual scene requirements. The inside of the liquid-cooled power cabinet is divided into power distribution compartment, power compartment and heat dissipation compartment. Because the size and interface of various functional modules of the same power level are unified, the structure of the power compartment can be uniformly designed, and various modules can be flexibly configured in practical applications. Realize different configurations of energy storage and charging power; the electrical configuration of the power distribution warehouse can be designed and prefabricated according to the different functions and power requirements of light, storage, and charging, and can be flexibly combined on site. Therefore, this set of liquid-cooled overcharge system has extremely high compatibility and flexibility.

05 High reliability

The refueling charging experience has always been the expectation of the majority of electric car owners, car companies and operators. With the increasing maturity of battery technology, the era of 5-minute fast charging may come much sooner than we expected. Full liquid-cooled supercharging will also become the mainstream choice for supercharging stations due to its high reliability, environmental friendliness and low TCO operating costs. Infypower will continue to be committed to the research and development of core technologies and products for power conversion , and provide the industry with a full range of liquid-cooled power conversion modules and the best liquid-cooled overcharging system solutions.

The key to solving the problem of queuing at fast charging stations is to achieve 5-minute charging, that is, to use high-power liquid-cooled super charging.

Domestic mainstream car companies have launched or will soon launch supercharged vehicles that support 800V platforms, realizing the experience of adding 200 kilometers of battery life after charging at 480kW within 5 minutes. However, most of the existing liquid-cooled supercharging piles use liquid-cooled charging guns on the basis of traditional air-cooled charging piles to achieve a maximum charging output of 600A. We call them semi-liquid-cooled supercharging piles for the time being. The power part of the semi-liquid-cooled overcharging pile is forced air-cooled heat dissipation. As the charging power increases, the noise also increases. At the same time, because the air flows through the pile body, the reliability of the charging pile is difficult to guarantee, and the later maintenance costs are higher. Corresponding to it is the full liquid-cooled supercharging pile, which uses a liquid-cooled charging module and a liquid-cooled charging gun. The overall system adopts a liquid-cooled heat dissipation design, which has the characteristics of large charging current, low noise and high reliability. The full liquid-cooled overcharging system is the development direction of liquid-cooled overcharging in the future.

02 Advantages of full liquid cooling charging

Advantage 1: High current

The output current of the charging pile is limited by the charging gun cable. The charging gun conducts electricity by the copper cable inside the gun wire, and the heating of the cable is proportional to the square value of the current. The larger the charging current, the greater the heating of the cable is. To reduce the heat generation of the cable and avoid overheating, the cross-sectional area of the wire must be increased, and of course the gun wire will be heavier. The current 250A national standard charging gun generally uses an 80mm 2 cable, and the overall charging gun is heavy and not easy to bend. If you want to achieve higher current charging, you can also use dual charging guns, but this is only an expedient measure for specific occasions. The ultimate solution for high current charging can only be charging with liquid-cooled charging guns.

There are cables and water pipes inside the liquid-cooled charging gun. The cable of the 500A liquid-cooled charging gun is usually only 35mm2 , and the cooling liquid in the water pipe flows to remove heat. Because the cable is thin, the liquid-cooled charging gun is 30%~40% lighter than the conventional charging gun. The liquid-cooled charging gun also needs to be equipped with a cooling unit, which consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to circulate in the gun line, bringing the heat to the radiator, and then blown away by the fan, so as to achieve a larger carrying capacity than conventional natural cooling charging guns.

Advantage 2: High reliability

The reliability of the charging pile depends largely on the reliability of the charging module, that is, it is greatly affected by the external environment of operation.

The key to solving the problem of queuing at fast charging stations is to achieve 5-minute charging, that is, to use high-power liquid-cooled super charging.

Domestic mainstream car companies have launched or will soon launch supercharged vehicles that support 800V platforms, realizing the experience of adding 200 kilometers of battery life after charging at 480kW within 5 minutes. However, most of the existing liquid-cooled supercharging piles use liquid-cooled charging guns on the basis of traditional air-cooled charging piles to achieve a maximum charging output of 600A. We call them semi-liquid-cooled supercharging piles for the time being. The power part of the semi-liquid-cooled overcharging pile is forced air-cooled heat dissipation. As the charging power increases, the noise also increases. At the same time, because the air flows through the pile body, the reliability of the charging pile is difficult to guarantee, and the later maintenance costs are higher. Corresponding to it is the full liquid-cooled supercharging pile, which uses a liquid-cooled charging module and a liquid-cooled charging gun. The overall system adopts a liquid-cooled heat dissipation design, which has the characteristics of large charging current, low noise and high reliability. The full liquid-cooled overcharging system is the development direction of liquid-cooled overcharging in the future.

02 Advantages of full liquid cooling charging

Advantage 1: High current

The output current of the charging pile is limited by the charging gun cable. The charging gun conducts electricity by the copper cable inside the gun wire, and the heating of the cable is proportional to the square value of the current. The larger the charging current, the greater the heating of the cable is. To reduce the heat generation of the cable and avoid overheating, the cross-sectional area of the wire must be increased, and of course the gun wire will be heavier. The current 250A national standard charging gun generally uses an 80mm 2 cable, and the overall charging gun is heavy and not easy to bend. If you want to achieve higher current charging, you can also use dual charging guns, but this is only an expedient measure for specific occasions. The ultimate solution for high current charging can only be charging with liquid-cooled charging guns.

There are cables and water pipes inside the liquid-cooled charging gun. The cable of the 500A liquid-cooled charging gun is usually only 35mm2 , and the cooling liquid in the water pipe flows to remove heat. Because the cable is thin, the liquid-cooled charging gun is 30%~40% lighter than the conventional charging gun. The liquid-cooled charging gun also needs to be equipped with a cooling unit, which consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to circulate in the gun line, bringing the heat to the radiator, and then blown away by the fan, so as to achieve a larger carrying capacity than conventional natural cooling charging guns.

Advantage 2: High reliability

The reliability of the charging pile depends largely on the reliability of the charging module, that is, it is greatly affected by the external environment of operation.

The cabinet of conventional charging piles and semi-liquid-cooled charging piles are air-cooled and dissipated. The air will be mixed with dust, salt mist and water vapor and adsorbed on the surface of internal devices, resulting in poor system insulation, poor heat dissipation, low charging efficiency, and reduced equipment life. For conventional charging piles or semi-liquid-cooled charging piles, heat dissipation and protection are two contradictory concepts. If the protection is good, the heat dissipation is difficult to design, and if the heat dissipation is good, the protection is difficult to handle.

The full liquid-cooled charging pile adopts a liquid-cooled charging module. There is no air duct on the front and back of the liquid-cooled module. The module relies on the cooling fluid circulated inside the liquid-cooled plate to exchange heat with the outside world, so that the power part of the charging pile can be fully enclosed to reduce heat dissipation. The radiator is external, and the heat is brought to the radiator through the coolant inside, and the external air blows away the heat on the surface of the radiator. The liquid-cooled charging module and electrical accessories in the charging pile have no contact with the external environment, so that IP65 protection can be achieved and the reliability is higher.

Advantage three: low noise

Conventional charging piles and semi-liquid-cooled charging piles have built-in air-cooled charging modules. The air-cooled modules have built-in multiple high-speed small fans, and the operating noise can reach above 65db. The noise is basically above 70dB when running at full power, which has little impact during the day, but is very disturbing at night. Therefore, the loud noise of the charging station is the most complained problem of the operators, and they have to rectify it if they are complained. However, the rectification cost is high and the effect is very limited. In the end, they have to reduce the power to reduce the noise.

The fully liquid-cooled charging pile adopts a dual-circulation heat dissipation structure. The internal liquid-cooled module relies on a water pump to drive the coolant to circulate heat, and transfers the heat generated by the module to the finned radiator. The heat dissipates from the device, and the noise of the fan with low speed and large air volume is much lower than that of the small fan with higher speed. The full liquid-cooled supercharging pile can also adopt a split-type heat dissipation design, which is similar to a split-type air conditioner. The heat dissipation unit is placed away from the crowd, and it can even exchange heat with pools and fountains to achieve better heat dissipation and lower temperature. noise.

Advantage 4: Low TCO

The cost of charging equipment at the charging station must be considered from the total life cycle cost (TCO) of the charging pile. The life of the traditional charging pile with air-cooled charging modules generally does not exceed 5 years, but the current lease period of the charging station operation is 8-10 years, which means that the charging equipment needs to be replaced at least once during the operation cycle of the station. In contrast, the service life of full liquid-cooled charging piles is at least 10 years, which can cover the entire life cycle of the station. At the same time, compared with the charging pile using the air-cooled module, which requires frequent operations such as opening the cabinet for dust removal and maintenance, the full liquid-cooled charging pile only needs to be washed after the external radiator has accumulated dust, and the maintenance is simple.

The TCO of the full liquid cooling charging system is lower than that of the traditional charging system using air-cooling charging modules, and with the wide application of the full liquid cooling system in batches, its cost-effective advantage will become more obvious.

03 The principle of full liquid cooling charging

The full liquid-cooled charging system uses a liquid-cooled charging module and a liquid-cooled charging gun, and the system as a whole uses liquid-cooled heat dissipation. As shown in the figure, the working principle of the integrated fully liquid-cooled charging system, the liquid-cooled charging gun and the liquid-cooled charging module share a cold source. The liquid cooling system consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to flow between the liquid cooling plate and the liquid cooling gun line of the liquid cooling module, bringing the heat to the radiator, and then blowing it away through a large air volume fan. After cooling down, the coolant returns to the water tank and circulates heat through the water pump repeatedly.

The power part of the system adopts liquid cooling to dissipate heat, and there is no air exchange with the external environment, so the design of IP65 can be realized. At the same time, the system uses a large air volume fan to dissipate heat with low noise and high environmental friendliness.

04 Infypower Source Technology - Liquid Cooled Charging Products

Infypower is the earliest enterprise in China that is committed to the development and actual batch application of liquid-cooled power conversion modules and full liquid-cooled charging systems.

Liquid Cooling Module

After several generations of liquid cooling module product iterations and technology accumulation, the current source liquid cooling power conversion modules cover three series of LRG series charging modules, LCG series DCDC DC conversion modules, and LBG series ACDC bidirectional conversion modules, which can meet the requirements of liquid cooling.

The cabinet of conventional charging piles and semi-liquid-cooled charging piles are air-cooled and dissipated. The air will be mixed with dust, salt mist and water vapor and adsorbed on the surface of internal devices, resulting in poor system insulation, poor heat dissipation, low charging efficiency, and reduced equipment life. For conventional charging piles or semi-liquid-cooled charging piles, heat dissipation and protection are two contradictory concepts. If the protection is good, the heat dissipation is difficult to design, and if the heat dissipation is good, the protection is difficult to handle.

The full liquid-cooled charging pile adopts a liquid-cooled charging module. There is no air duct on the front and back of the liquid-cooled module. The module relies on the cooling fluid circulated inside the liquid-cooled plate to exchange heat with the outside world, so that the power part of the charging pile can be fully enclosed to reduce heat dissipation. The radiator is external, and the heat is brought to the radiator through the coolant inside, and the external air blows away the heat on the surface of the radiator. The liquid-cooled charging module and electrical accessories in the charging pile have no contact with the external environment, so that IP65 protection can be achieved and the reliability is higher.

Advantage three: low noise

Conventional charging piles and semi-liquid-cooled charging piles have built-in air-cooled charging modules. The air-cooled modules have built-in multiple high-speed small fans, and the operating noise can reach above 65db. The noise is basically above 70dB when running at full power, which has little impact during the day, but is very disturbing at night. Therefore, the loud noise of the charging station is the most complained problem of the operators, and they have to rectify it if they are complained. However, the rectification cost is high and the effect is very limited. In the end, they have to reduce the power to reduce the noise.

The fully liquid-cooled charging pile adopts a dual-circulation heat dissipation structure. The internal liquid-cooled module relies on a water pump to drive the coolant to circulate heat, and transfers the heat generated by the module to the finned radiator. The heat dissipates from the device, and the noise of the fan with low speed and large air volume is much lower than that of the small fan with higher speed. The full liquid-cooled supercharging pile can also adopt a split-type heat dissipation design, which is similar to a split-type air conditioner. The heat dissipation unit is placed away from the crowd, and it can even exchange heat with pools and fountains to achieve better heat dissipation and lower temperature. noise.

Advantage 4: Low TCO

The cost of charging equipment at the charging station must be considered from the total life cycle cost (TCO) of the charging pile. The life of the traditional charging pile with air-cooled charging modules generally does not exceed 5 years, but the current lease period of the charging station operation is 8-10 years, which means that the charging equipment needs to be replaced at least once during the operation cycle of the station. In contrast, the service life of full liquid-cooled charging piles is at least 10 years, which can cover the entire life cycle of the station. At the same time, compared with the charging pile using the air-cooled module, which requires frequent operations such as opening the cabinet for dust removal and maintenance, the full liquid-cooled charging pile only needs to be washed after the external radiator has accumulated dust, and the maintenance is simple.

The TCO of the full liquid cooling charging system is lower than that of the traditional charging system using air-cooling charging modules, and with the wide application of the full liquid cooling system in batches, its cost-effective advantage will become more obvious.

03 The principle of full liquid cooling charging

The full liquid-cooled charging system uses a liquid-cooled charging module and a liquid-cooled charging gun, and the system as a whole uses liquid-cooled heat dissipation. As shown in the figure, the working principle of the integrated fully liquid-cooled charging system, the liquid-cooled charging gun and the liquid-cooled charging module share a cold source. The liquid cooling system consists of a water tank, a water pump, a radiator and a fan. The water pump drives the coolant to flow between the liquid cooling plate and the liquid cooling gun line of the liquid cooling module, bringing the heat to the radiator, and then blowing it away through a large air volume fan. After cooling down, the coolant returns to the water tank and circulates heat through the water pump repeatedly.

The power part of the system adopts liquid cooling to dissipate heat, and there is no air exchange with the external environment, so the design of IP65 can be realized. At the same time, the system uses a large air volume fan to dissipate heat with low noise and high environmental friendliness.

04 Infypower Source Technology - Liquid Cooled Charging Products

Infypower is the earliest enterprise in China that is committed to the development and actual batch application of liquid-cooled power conversion modules and full liquid-cooled charging systems.

Liquid Cooling Module

After several generations of liquid cooling module product iterations and technology accumulation, the current source liquid cooling power conversion modules cover three series of LRG series charging modules, LCG series DCDC DC conversion modules, and LBG series ACDC bidirectional conversion modules, which can meet the requirements of liquid cooling.

The liquid-cooled power conversion module has the advantages of low noise and high reliability. Infypower also unifies the size and interface design of the charging module, DCDC conversion module, and ACDC bidirectional module of the same power level, so that it can be used in overcharging systems, storage and charging. During the design process of the system, a unified structure and heat dissipation design can be carried out. In specific applications, the charging module or storage and charging module can be configured according to the actual situation to achieve high compatibility of system design.

Liquid Cooled Overcharge System

For medium-power fast charging applications, Infypower has launched an integrated 240kW full liquid-cooled fast charging system as shown in the figure. The system is equipped with six 40kW liquid-cooled charging modules, a 250A conventional charging gun and a 500A liquid-cooled charging module. charging gun. The liquid-cooled output port can achieve a full power output of 240kW, and can charge a passenger car (Tesla, Jikrypton, etc.) on a 400V platform at a maximum of 500A. At the same time, the system has extremely low noise, high reliability, and light gun wires, and can be widely used in high-end charging places such as residential areas, office areas, and brand charging stations.

The liquid-cooled power conversion module has the advantages of low noise and high reliability. Infypower also unifies the size and interface design of the charging module, DCDC conversion module, and ACDC bidirectional module of the same power level, so that it can be used in overcharging systems, storage and charging. During the design process of the system, a unified structure and heat dissipation design can be carried out. In specific applications, the charging module or storage and charging module can be configured according to the actual situation to achieve high compatibility of system design.

Liquid Cooled Overcharge System

For medium-power fast charging applications, Infypower has launched an integrated 240kW full liquid-cooled fast charging system as shown in the figure. The system is equipped with six 40kW liquid-cooled charging modules, a 250A conventional charging gun and a 500A liquid-cooled charging module. charging gun. The liquid-cooled output port can achieve a full power output of 240kW, and can charge a passenger car (Tesla, Jikrypton, etc.) on a 400V platform at a maximum of 500A. At the same time, the system has extremely low noise, high reliability, and light gun wires, and can be widely used in high-end charging places such as residential areas, office areas, and brand charging stations.

For high-power overcharging applications, Infypower has launched a 640kW split-type fully liquid-cooled overcharging system as shown in the figure below. The system adopts a split-type design and consists of a liquid-cooled power cabinet and a liquid-cooled charging terminal. The side of the liquid-cooled power supply cabinet dissipates heat, and the protection level of the power part can reach IP65; the power is dynamically distributed among the liquid-cooled charging terminals, and a single gun can achieve a maximum power output of 480kW, which can increase the mileage of 200+ kilometers after charging for 5 minutes. The system has the advantages of low noise, high reliability, and simple maintenance. It can be widely used in various super charging stations and brand charging stations to provide car owners with a high-quality charging experience.

Liquid cooling storage and charging system

Liquid-cooled overcharging is the development direction of high-power charging, but the batch deployment of overcharging is facing the problem of insufficient power distribution capacity. The power distribution capacity required by an overcharging system is equivalent to the power capacity required by a residential building. The power distribution demand of the overcharging site is equivalent to the power demand of a residential area. The best solution to solve the problem of insufficient power distribution capacity at overcharging sites is to increase energy storage facilities, that is, liquid-cooled energy storage and charging. In view of this, Infypower has launched an 800kW full liquid-cooled storage and charging system.

Infypower's liquid-cooled storage and charging system adopts an AC-DC hybrid bus architecture, the AC bus is connected to the power grid, and the DC bus is connected to the energy storage battery. The electrical connection between the energy storage battery and the overcharging system is the DC bus, and the DC bus can also be easily connected to the photovoltaic module through the DCDC module, and the energy conversion efficiency is 3%~4% higher than that of the conventional AC bus.

Infypower’s fully liquid-cooled storage and charging system adopts a modular design, and can configure energy storage/charging power, energy storage battery capacity, and the number of charging terminals according to actual scene requirements. The inside of the liquid-cooled power cabinet is divided into power distribution compartment, power compartment and heat dissipation compartment. Because the size and interface of various functional modules of the same power level are unified, the structure of the power compartment can be uniformly designed, and various modules can be flexibly configured in practical applications. Realize different configurations of energy storage and charging power; the electrical configuration of the power distribution warehouse can be designed and prefabricated according to the different functions and power requirements of light, storage, and charging, and can be flexibly combined on site. Therefore, this set of liquid-cooled overcharge system has extremely high compatibility and flexibility.

05 High reliability

The refueling charging experience has always been the expectation of the majority of electric car owners, car companies and operators. With the increasing maturity of battery technology, the era of 5-minute fast charging may come much sooner than we expected. Full liquid-cooled supercharging will also become the mainstream choice for supercharging stations due to its high reliability, environmental friendliness and low TCO operating costs. Infypower will continue to be committed to the research and development of core technologies and products for power conversion , and provide the industry with a full range of liquid-cooled power conversion modules and the best liquid-cooled overcharging system solutions.

For high-power overcharging applications, Infypower has launched a 640kW split-type fully liquid-cooled overcharging system as shown in the figure below. The system adopts a split-type design and consists of a liquid-cooled power cabinet and a liquid-cooled charging terminal. The side of the liquid-cooled power supply cabinet dissipates heat, and the protection level of the power part can reach IP65; the power is dynamically distributed among the liquid-cooled charging terminals, and a single gun can achieve a maximum power output of 480kW, which can increase the mileage of 200+ kilometers after charging for 5 minutes. The system has the advantages of low noise, high reliability, and simple maintenance. It can be widely used in various super charging stations and brand charging stations to provide car owners with a high-quality charging experience.

Liquid cooling storage and charging system

Liquid-cooled overcharging is the development direction of high-power charging, but the batch deployment of overcharging is facing the problem of insufficient power distribution capacity. The power distribution capacity required by an overcharging system is equivalent to the power capacity required by a residential building. The power distribution demand of the overcharging site is equivalent to the power demand of a residential area. The best solution to solve the problem of insufficient power distribution capacity at overcharging sites is to increase energy storage facilities, that is, liquid-cooled energy storage and charging. In view of this, Infypower has launched an 800kW full liquid-cooled storage and charging system.

Infypower's liquid-cooled storage and charging system adopts an AC-DC hybrid bus architecture, the AC bus is connected to the power grid, and the DC bus is connected to the energy storage battery. The electrical connection between the energy storage battery and the overcharging system is the DC bus, and the DC bus can also be easily connected to the photovoltaic module through the DCDC module, and the energy conversion efficiency is 3%~4% higher than that of the conventional AC bus.

Infypower’s fully liquid-cooled storage and charging system adopts a modular design, and can configure energy storage/charging power, energy storage battery capacity, and the number of charging terminals according to actual scene requirements. The inside of the liquid-cooled power cabinet is divided into power distribution compartment, power compartment and heat dissipation compartment. Because the size and interface of various functional modules of the same power level are unified, the structure of the power compartment can be uniformly designed, and various modules can be flexibly configured in practical applications. Realize different configurations of energy storage and charging power; the electrical configuration of the power distribution warehouse can be designed and prefabricated according to the different functions and power requirements of light, storage, and charging, and can be flexibly combined on site. Therefore, this set of liquid-cooled overcharge system has extremely high compatibility and flexibility.

05 High reliability

The refueling charging experience has always been the expectation of the majority of electric car owners, car companies and operators. With the increasing maturity of battery technology, the era of 5-minute fast charging may come much sooner than we expected. Full liquid-cooled supercharging will also become the mainstream choice for supercharging stations due to its high reliability, environmental friendliness and low TCO operating costs. Infypower will continue to be committed to the research and development of core technologies and products for power conversion , and provide the industry with a full range of liquid-cooled power conversion modules and the best liquid-cooled overcharging system solutions. -

PreviousInfypower: Leading the "Blue Ocean Variables" in the "Red Ocean Market"March 01, 2023

-

NextInfypower is seeking applications for the role of Business Development Manager, based in Munich office. The role will be responsible for the coordination and management of new and current EV charging station and Energy Storage projects in EU.February 13, 2023

Share this article