Infypower showcased liquid cooling charger power module in Shenzhen CPTE Exhibition 2021

December 29, 2021

2021 Shenzhen Charging Pile Exhibition was held in the Municipal Conven-tion and Exhibition Center from December 1 st to December 3 rd . In spite of the challenges and uncertainties brought by corona virus, the exhibition was well visited by interested professionals and it saw great enthusiasm people have for the renewable energy industry.

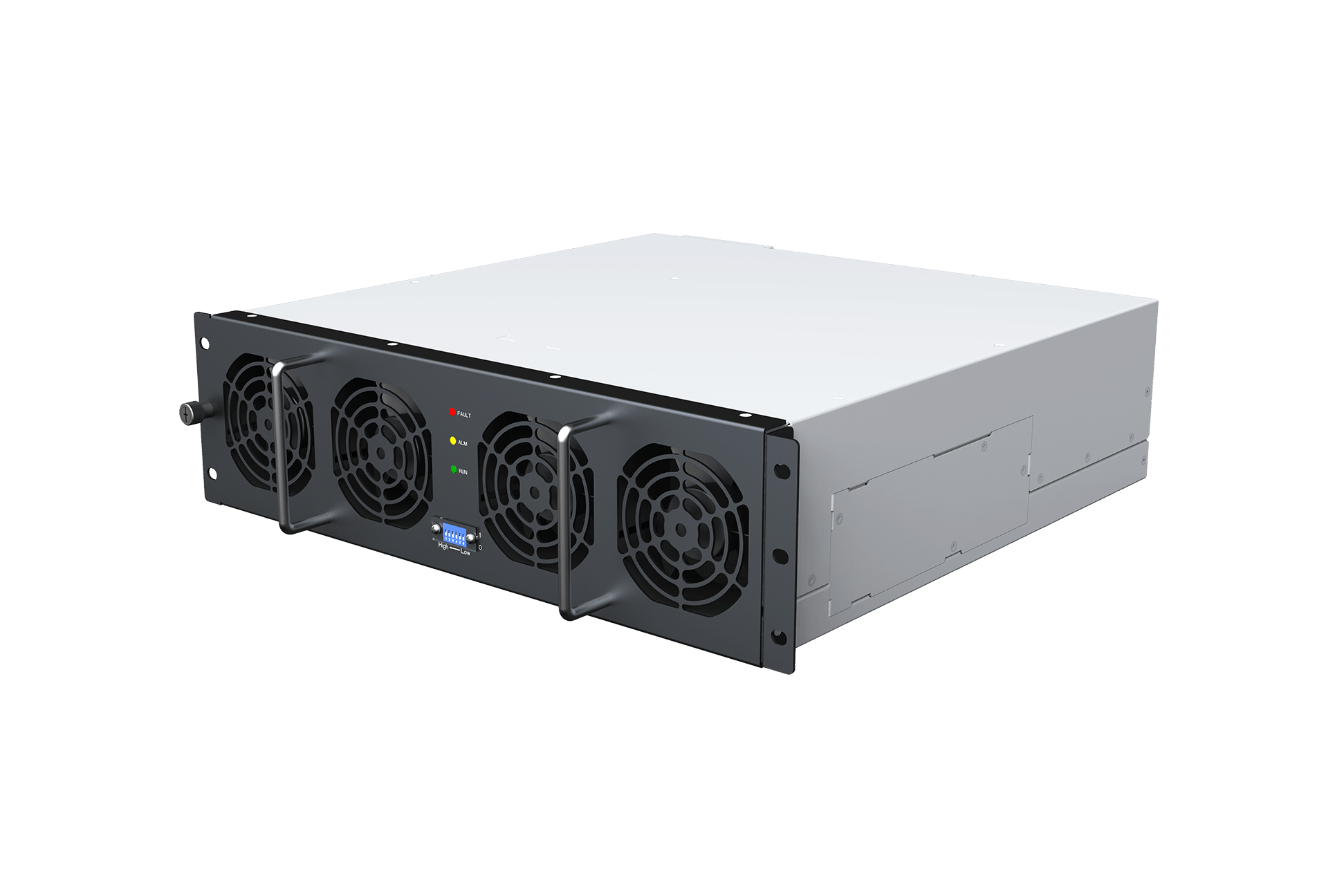

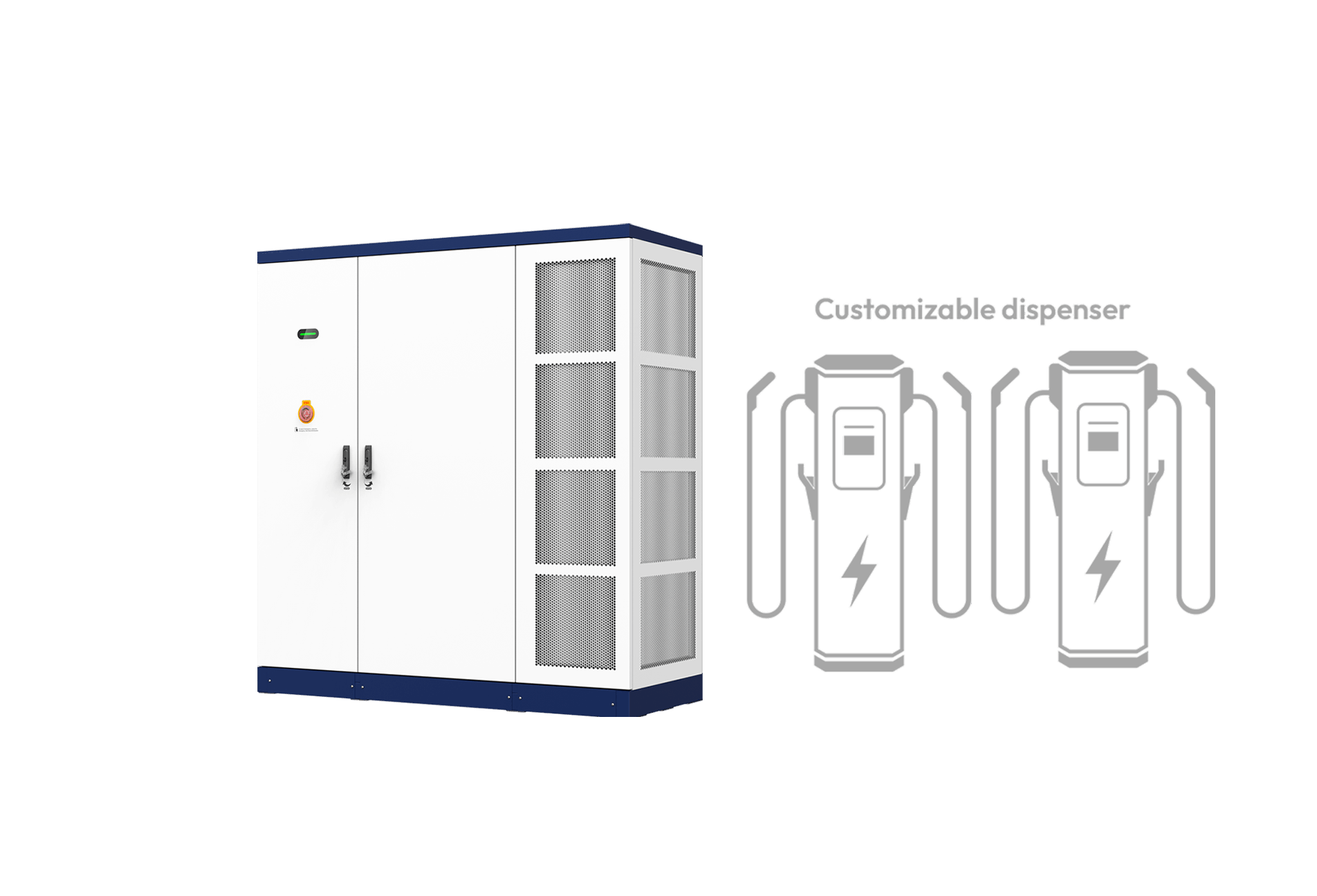

Infypower booth showcased its liquid-cooled charger power module, in addition to previously well-recognized fan-cooling 40/ 30/ 20kW charger power module, 30/ 20kW charger power module series, and 22kW bidirec-tional power converter. Once coming out, the liquid cooling module became the focus of the scene and attracted wide attention from charging system operators.

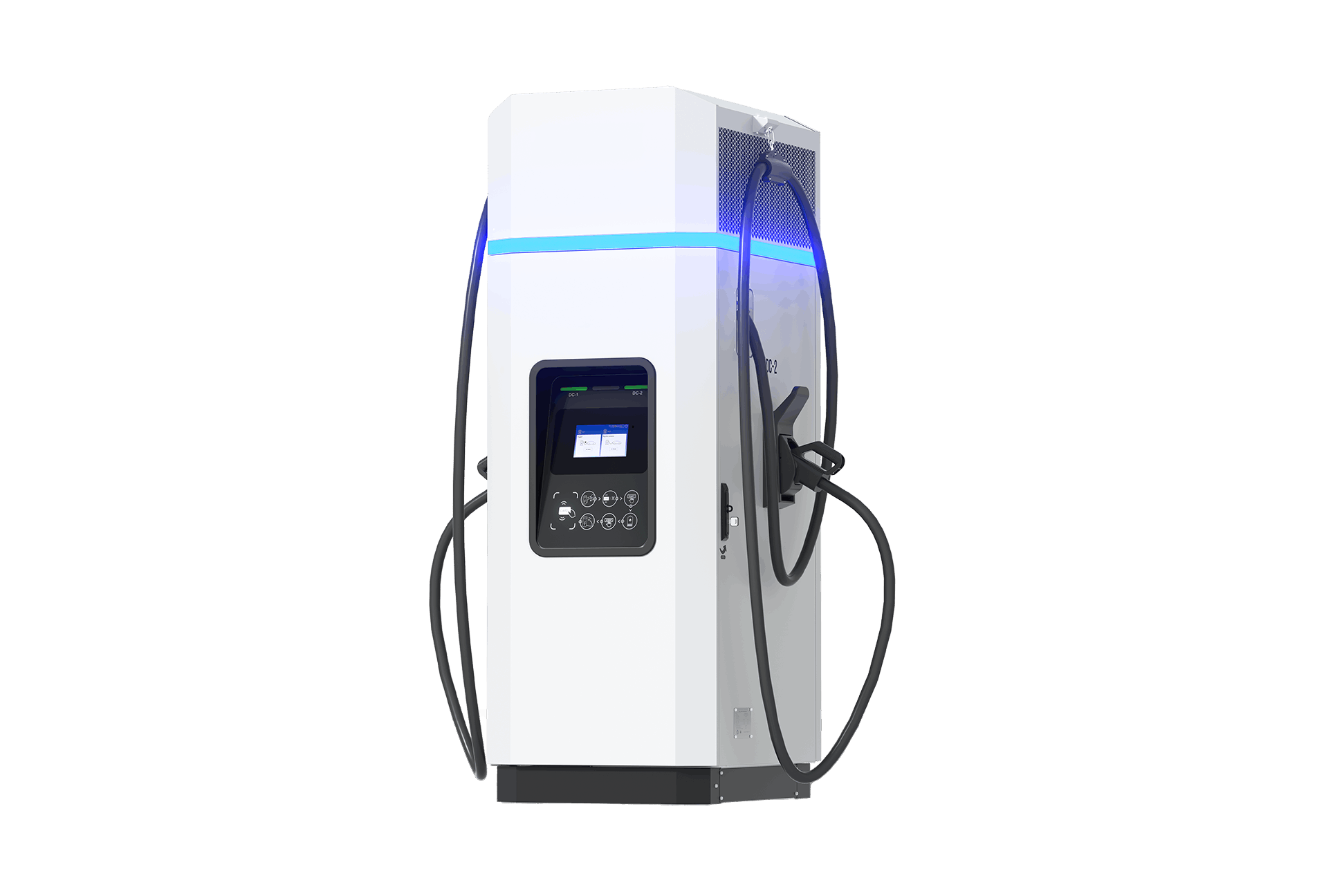

With the prevalent application of 4C/6C EV charging, there is no doubt that high-power super charge will become dominant in the upcoming future. However, traditional high-power charging system equipped with air cooling modules has persistent problems in fault occurrence and high noises. If the charging pile breaks down frequently, the operator is liable to hurting cus- tomer experience and taking incalculable damage to its brand name. As for the noise, Beijing Business Daily and China Youth Daily reported adding-up noises caused by module air cooling and charger fan dissipation exceed -70dB, which is incompliant to GB22337-2008 acoustic requirement on a serious scale.

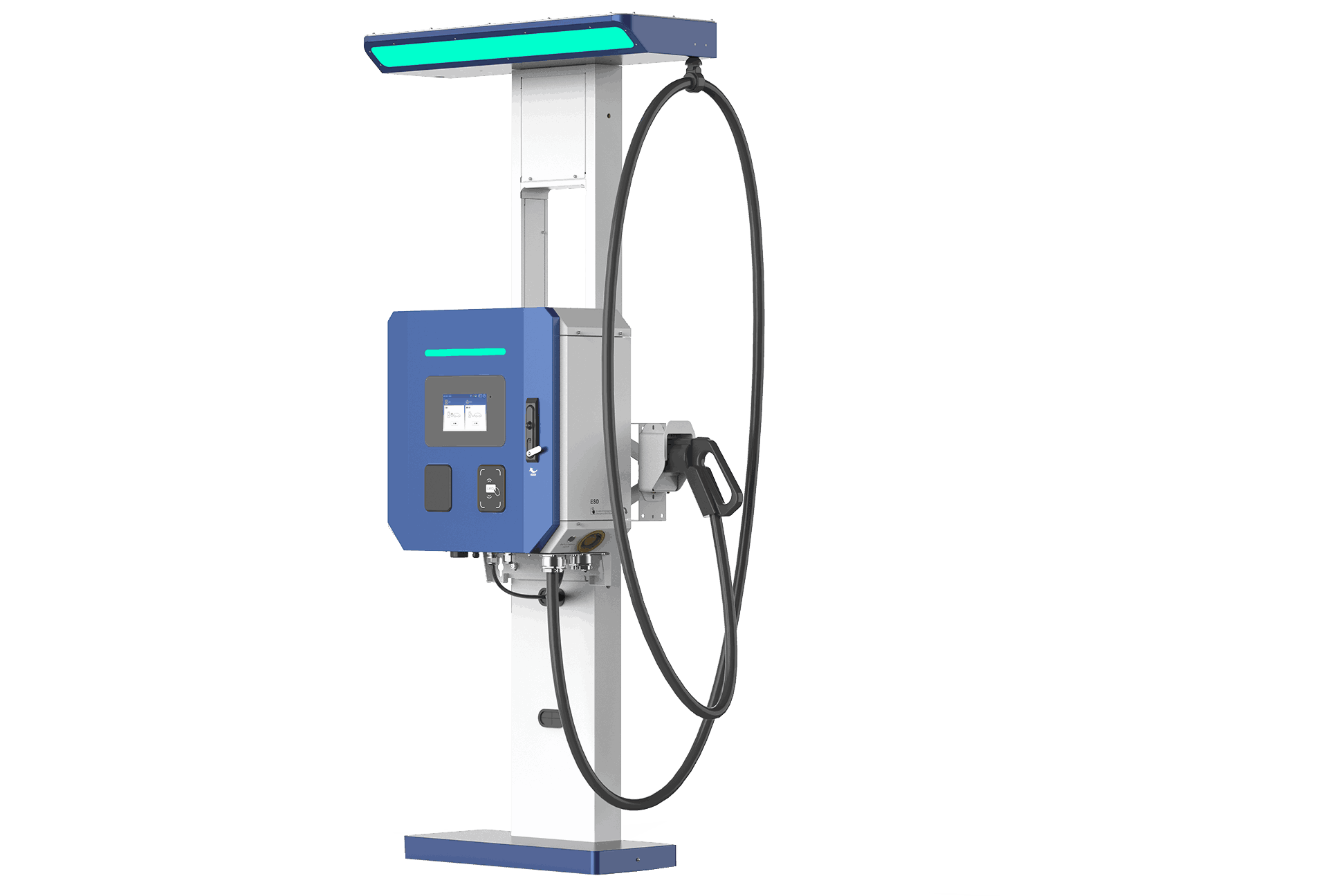

In terms of these concerns, Infypower released LRG1K0100G which abandon disturbing fan and choose water pump to drive the coolant for heat dissipation. The liquid cooling module makes zero noise itself and the charger adopts high-volume low-frequency fan to minimize output acoustic level of the charging system.

LRG1K0100G module is designed with fully sealed water-proof protection and rust prevention. It supports hot plug in both electric and liquid interfaces. Also, the module is suitable for most EV as it covers a wide range of output voltage from 150Ddc to 1000Vd, and input voltage from 260Vac to 530Vac. Currently 30kW/1000V LRG1K0100G has cleared TUV CE/UL registration, and EMC class B level. Infypower will expand the series to release 40kW/50kW power modules, which are perfectly compatible with LRG1K0100G in both size and interface. Last but not least, the liquid modules work with perfect silence.

It is safely predicted that LRG1K0100G will be widely used in harsh environments such as high dust mining sites, high temperature or high humidity sites, salt fog coastal areas and typhoon-prone seaside. Also, its explosion proof function can help the module applied in gas stations and underground mines. Areas sensitive to high noise level, such as residential and office places will also prefer the liquefied modules.

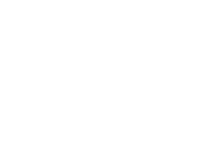

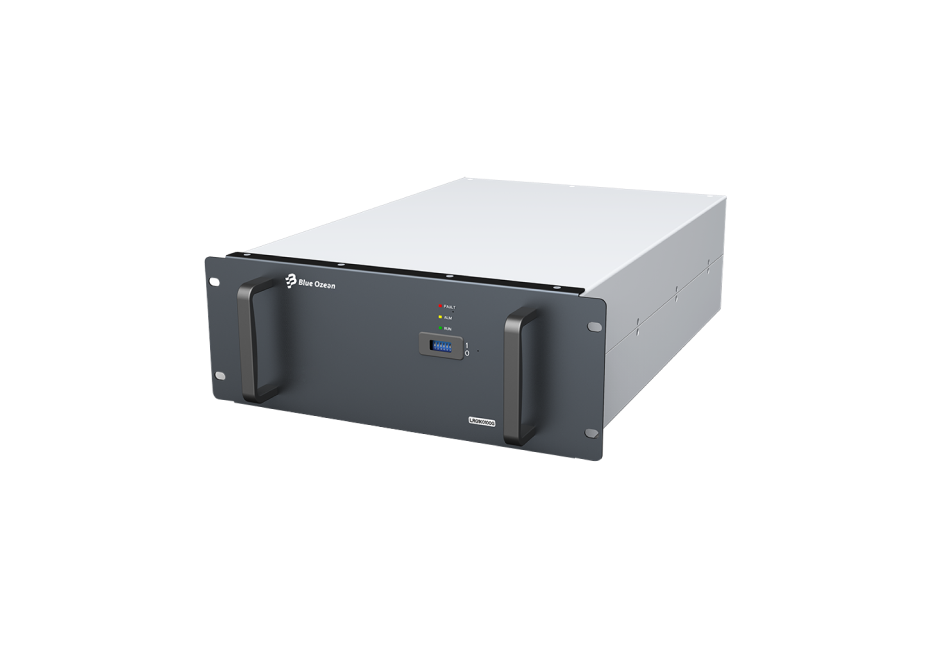

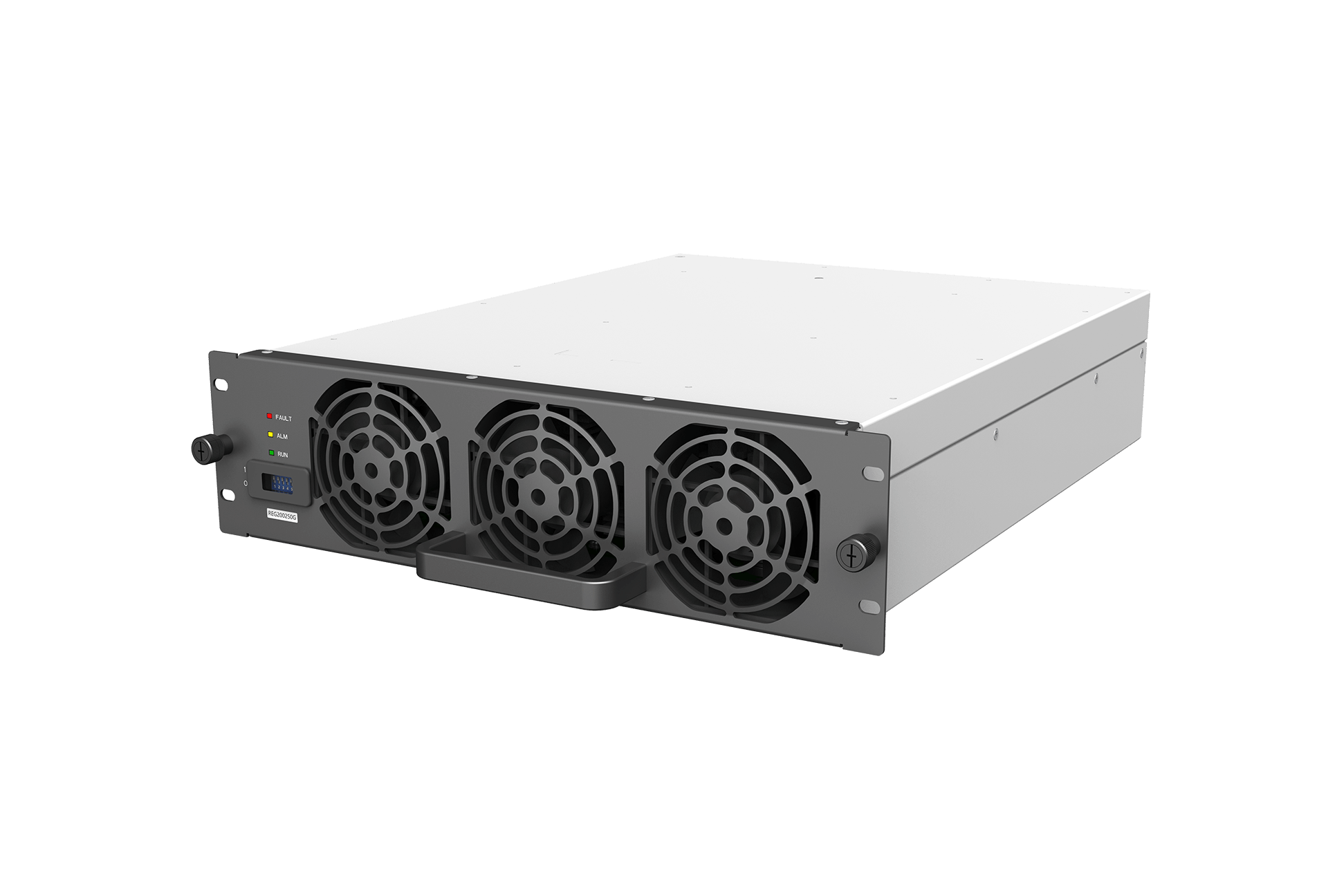

Front panel of module

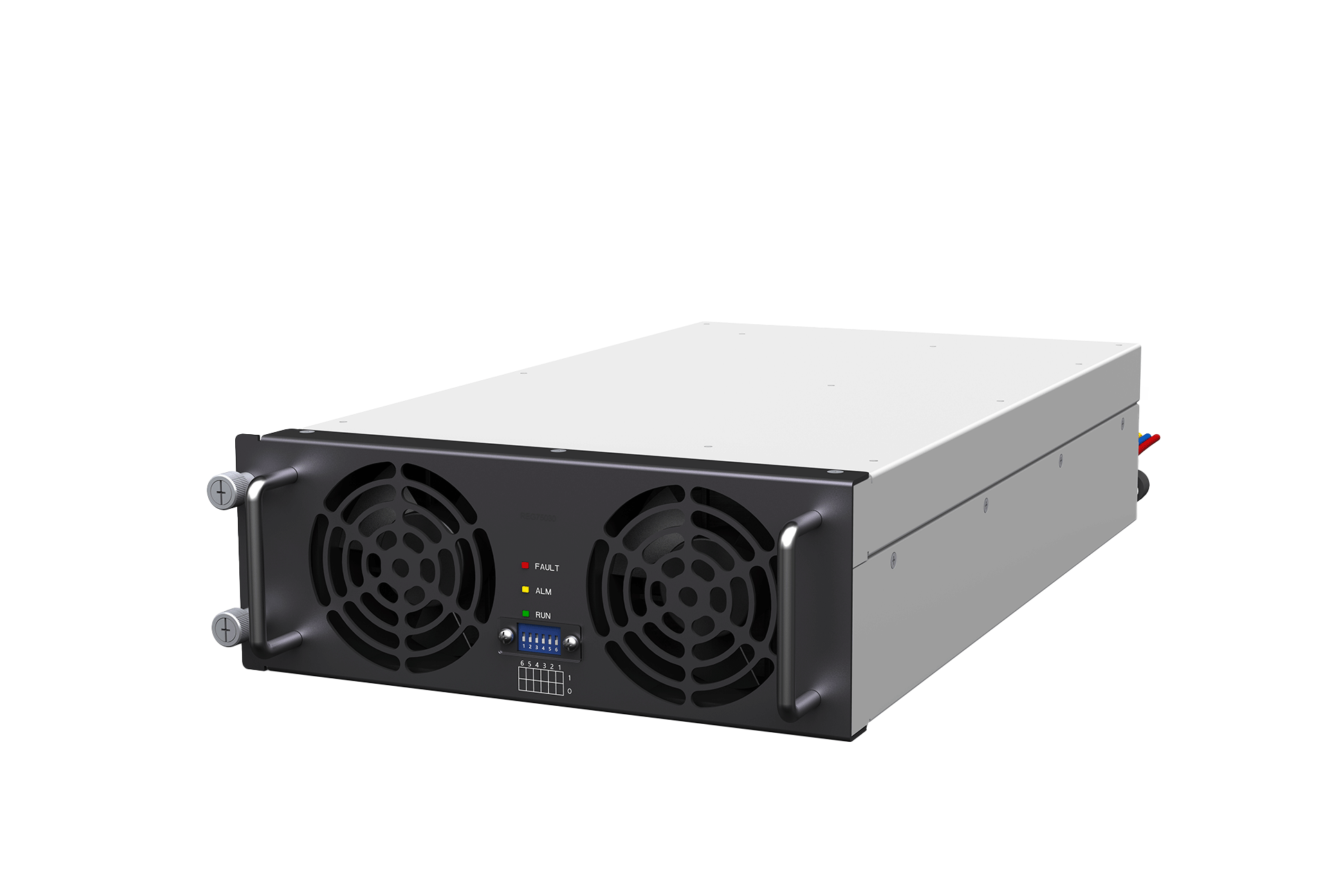

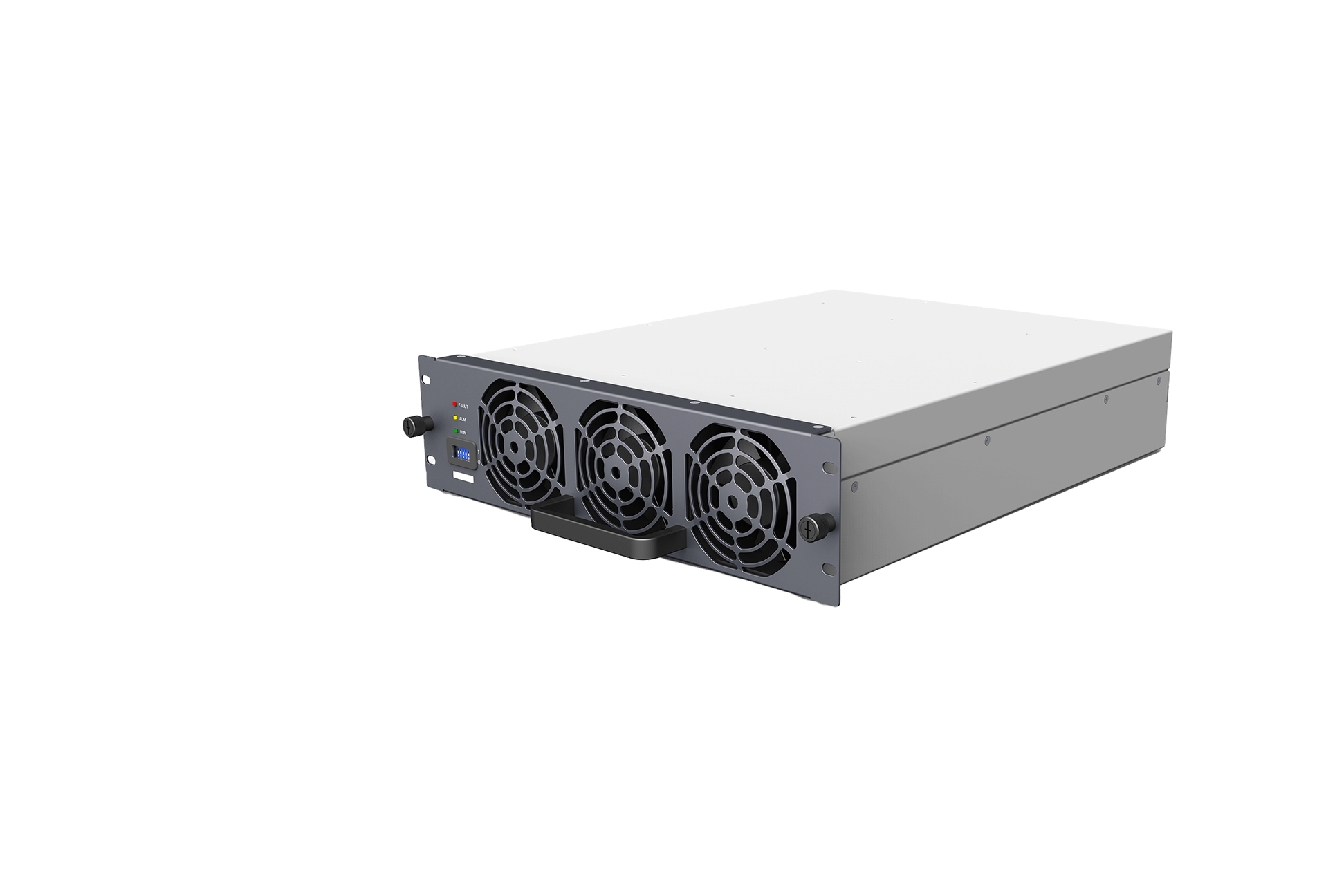

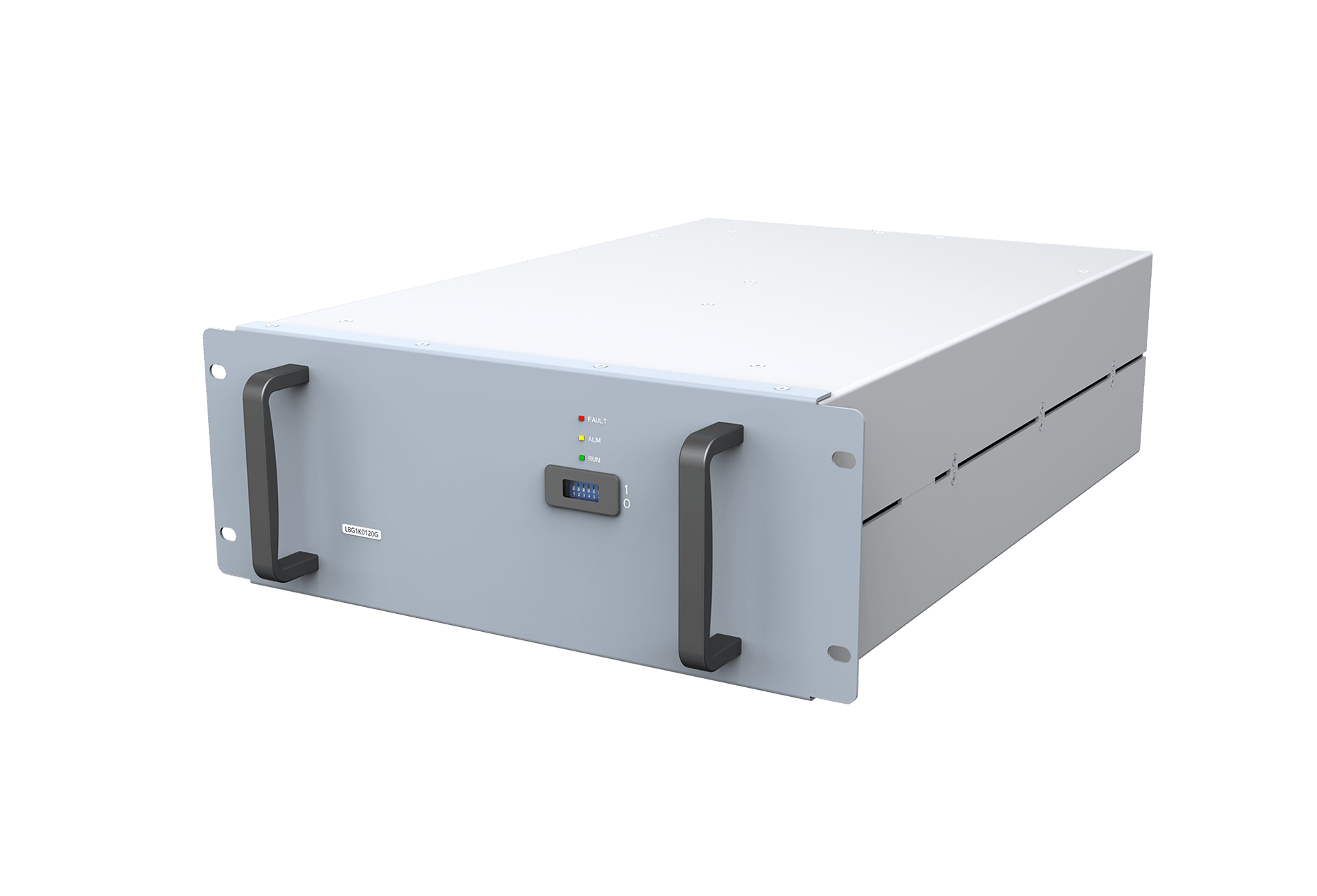

Fill in water via the shown board for heat exchange and evacuate later.

Fill in water via the shown board for heat exchange and evacuate later.

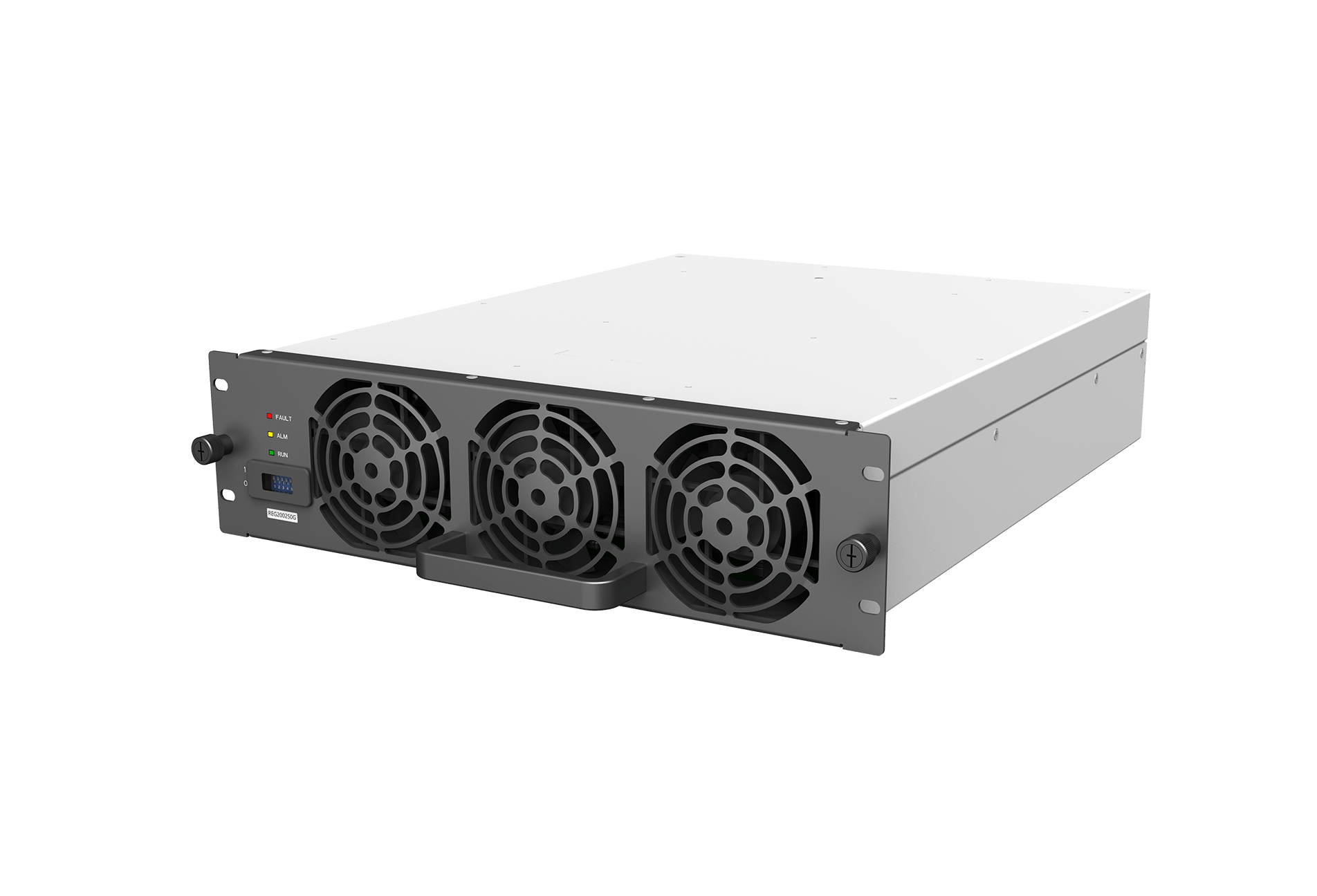

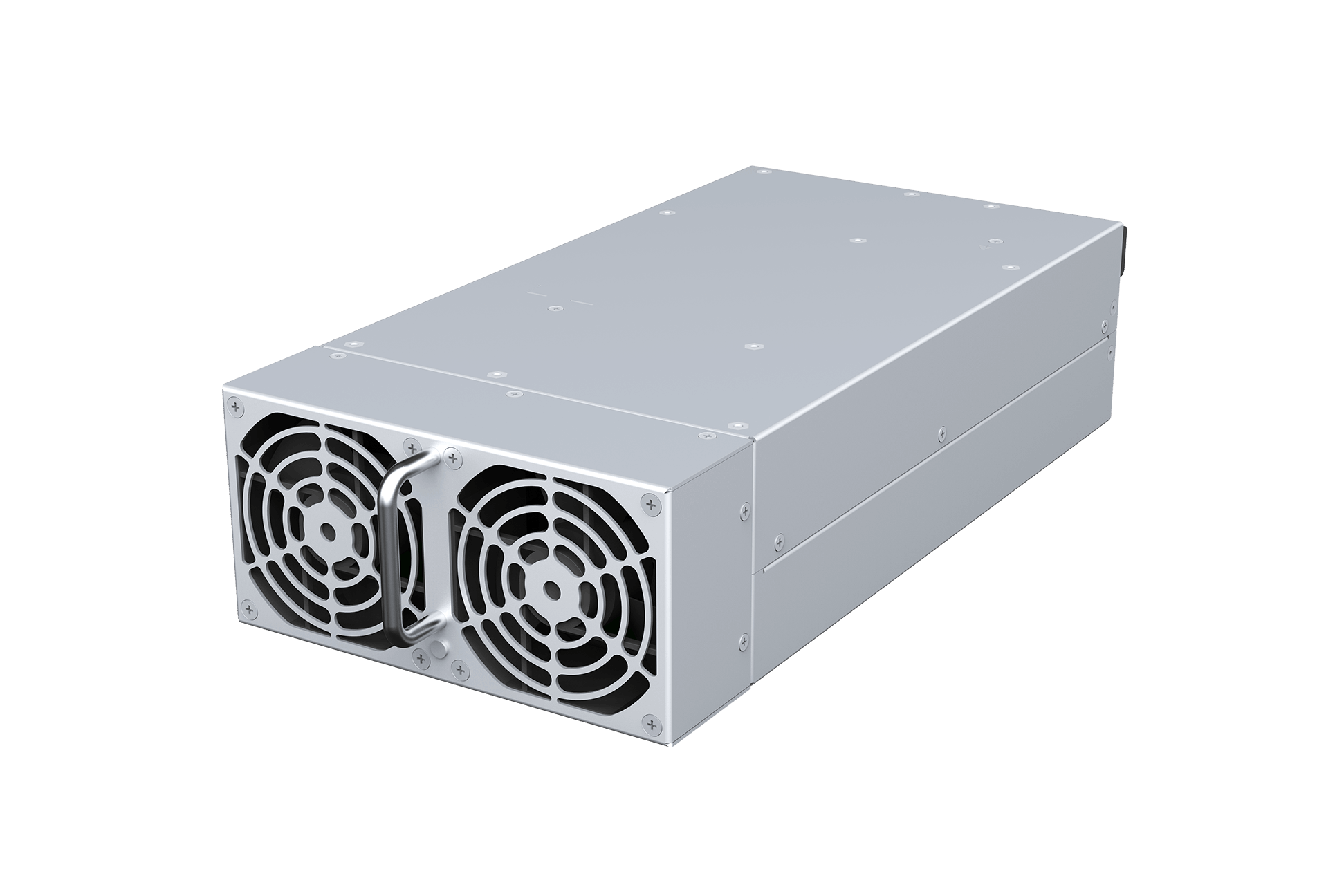

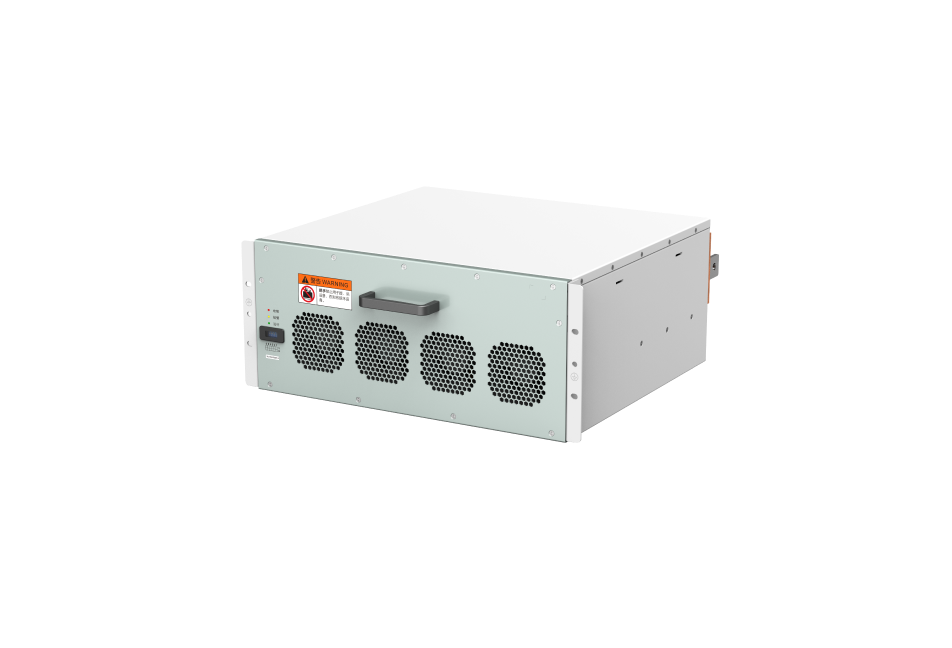

The interior module is simply separated from the dust, salt spray and humidity in outside environment

The interior module is simply separated from the dust, salt spray and humidity in outside environment

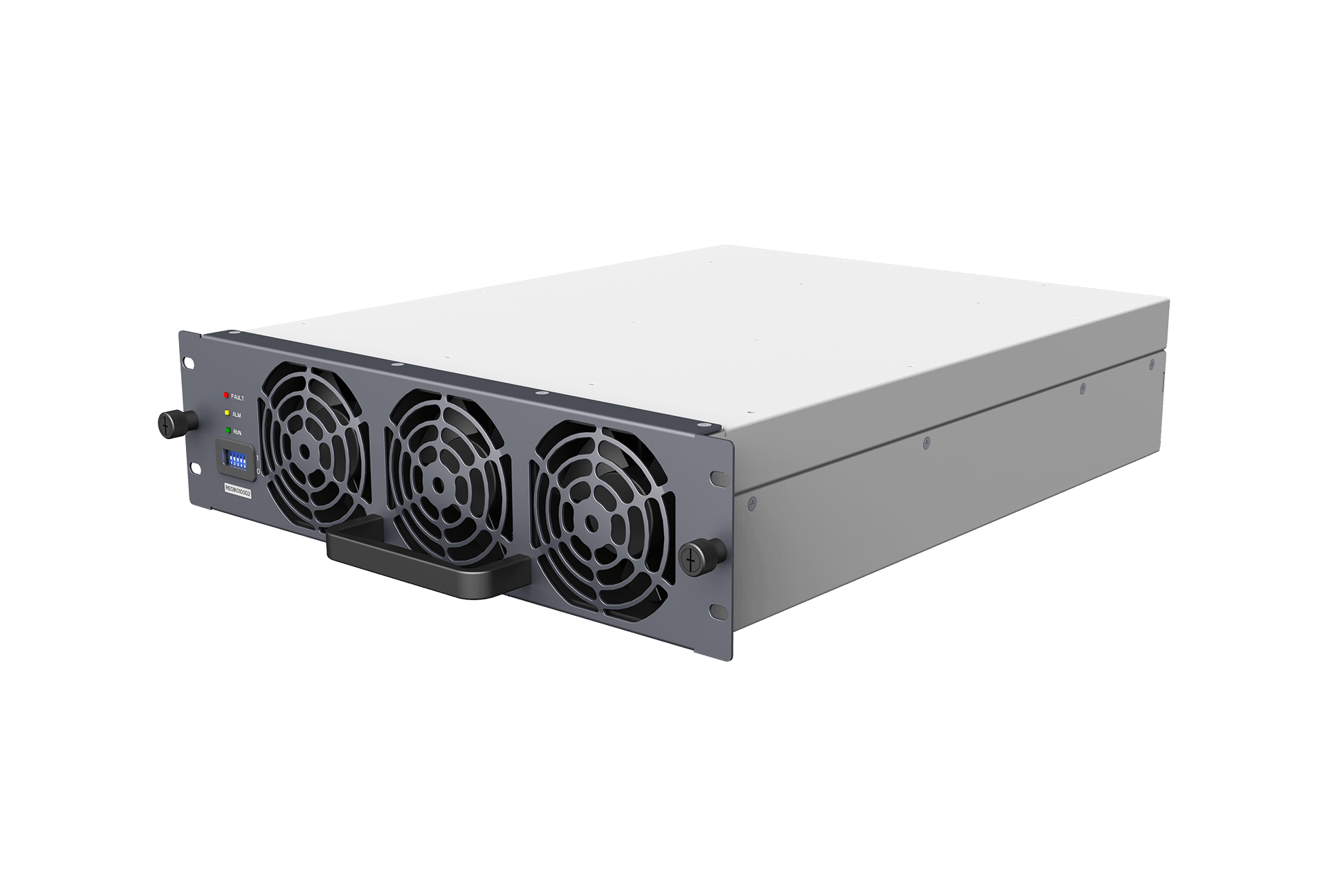

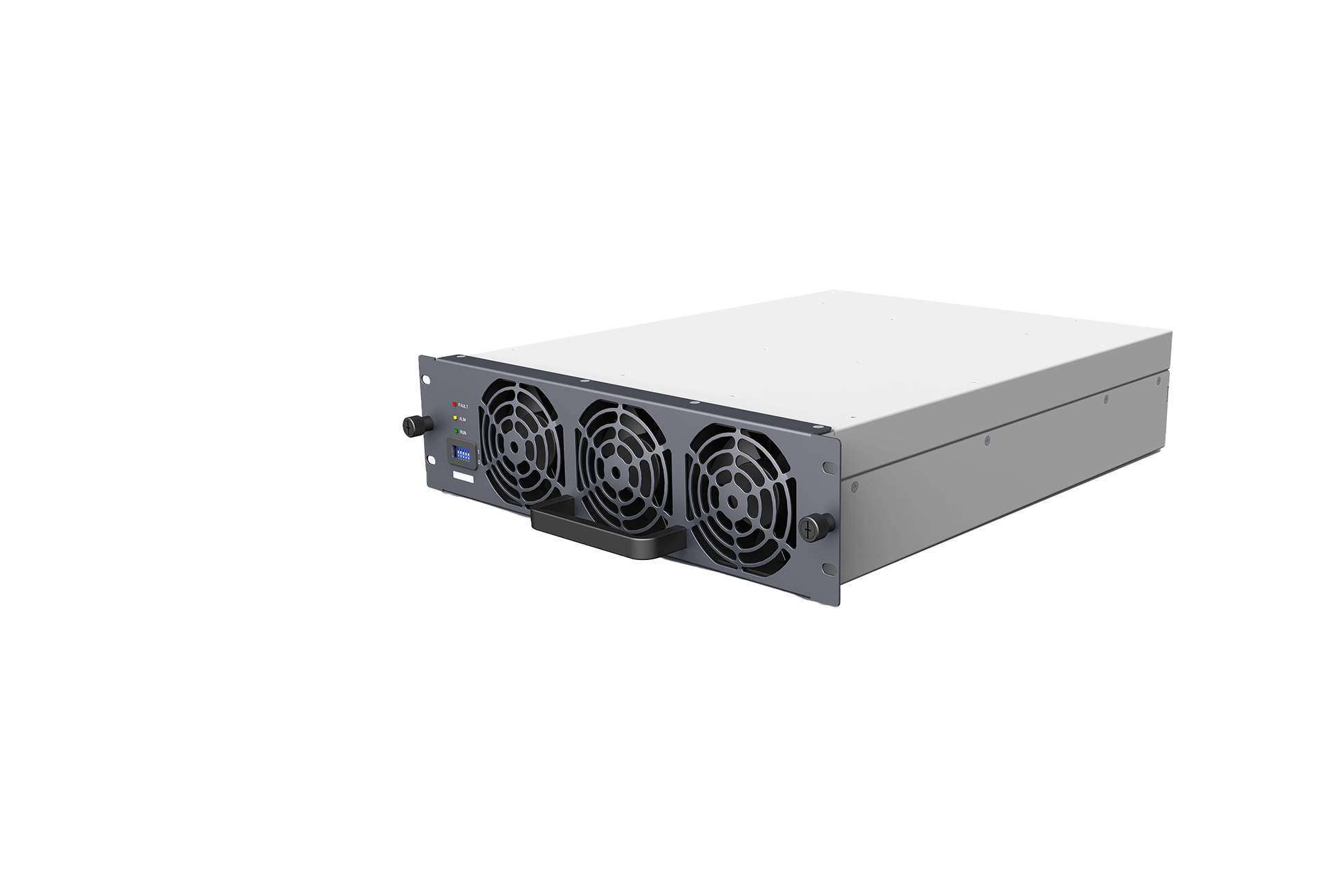

Coolant is driven by an external pump to eliminate module noises.

Coolant is driven by an external pump to eliminate module noises.

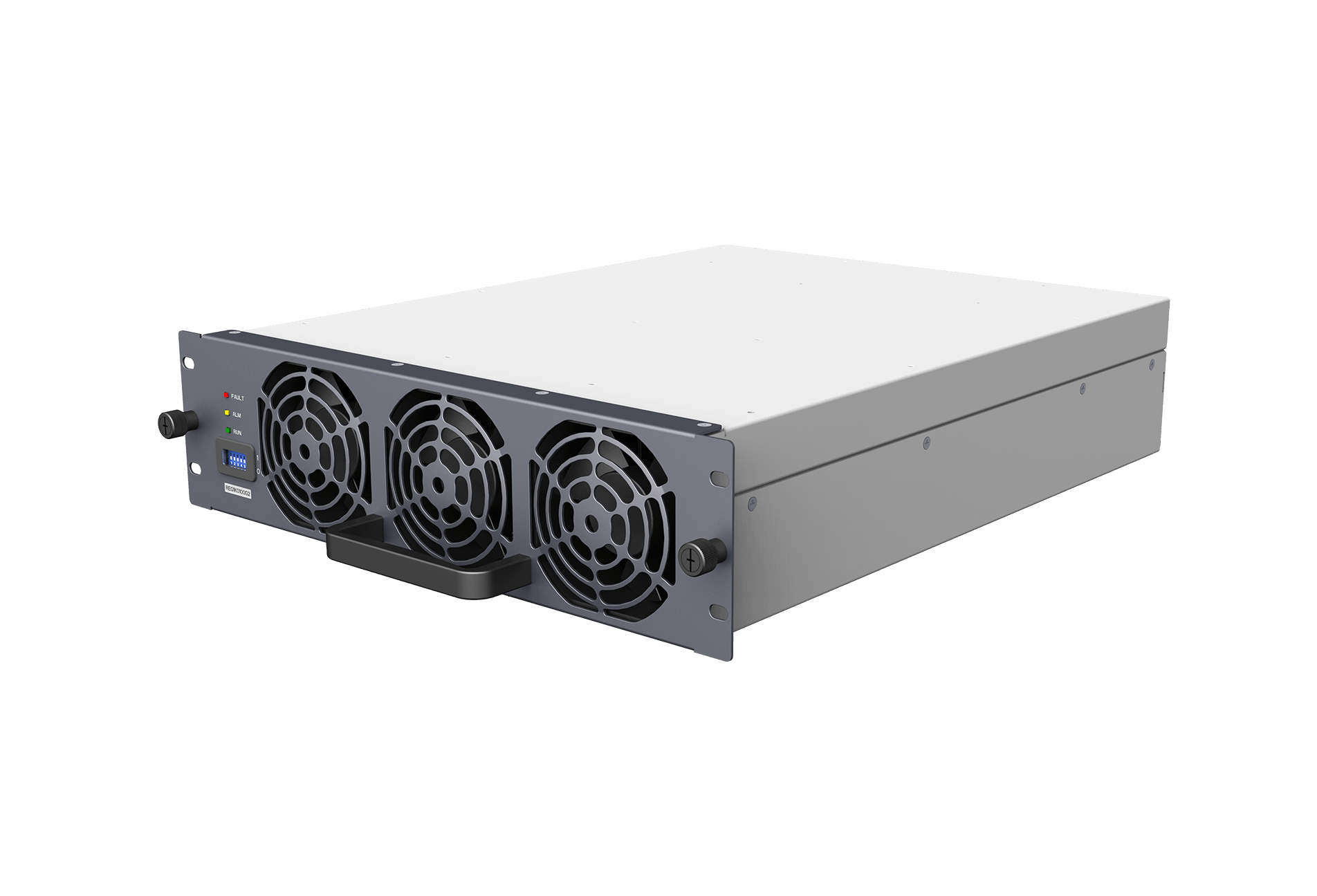

Feature of liquid cooling module

Traditional air-cooled EV charger generally have IP54 protection and failure rate remain higher in application scenarios such as dusty construction sites, high temperature, high humidity and high salt spray areas. Liquid-cooled charging systems can easily realize IP65 design to meet various requirements in such harsh scenarios.

The liquid-cooled charging module is equipped with zero noise and adopts a variety of thermal management, such as refrigerant heat exchange, water-cooled and air-conditioning, all contributing to desirable heat dissipa- tion and noise control.

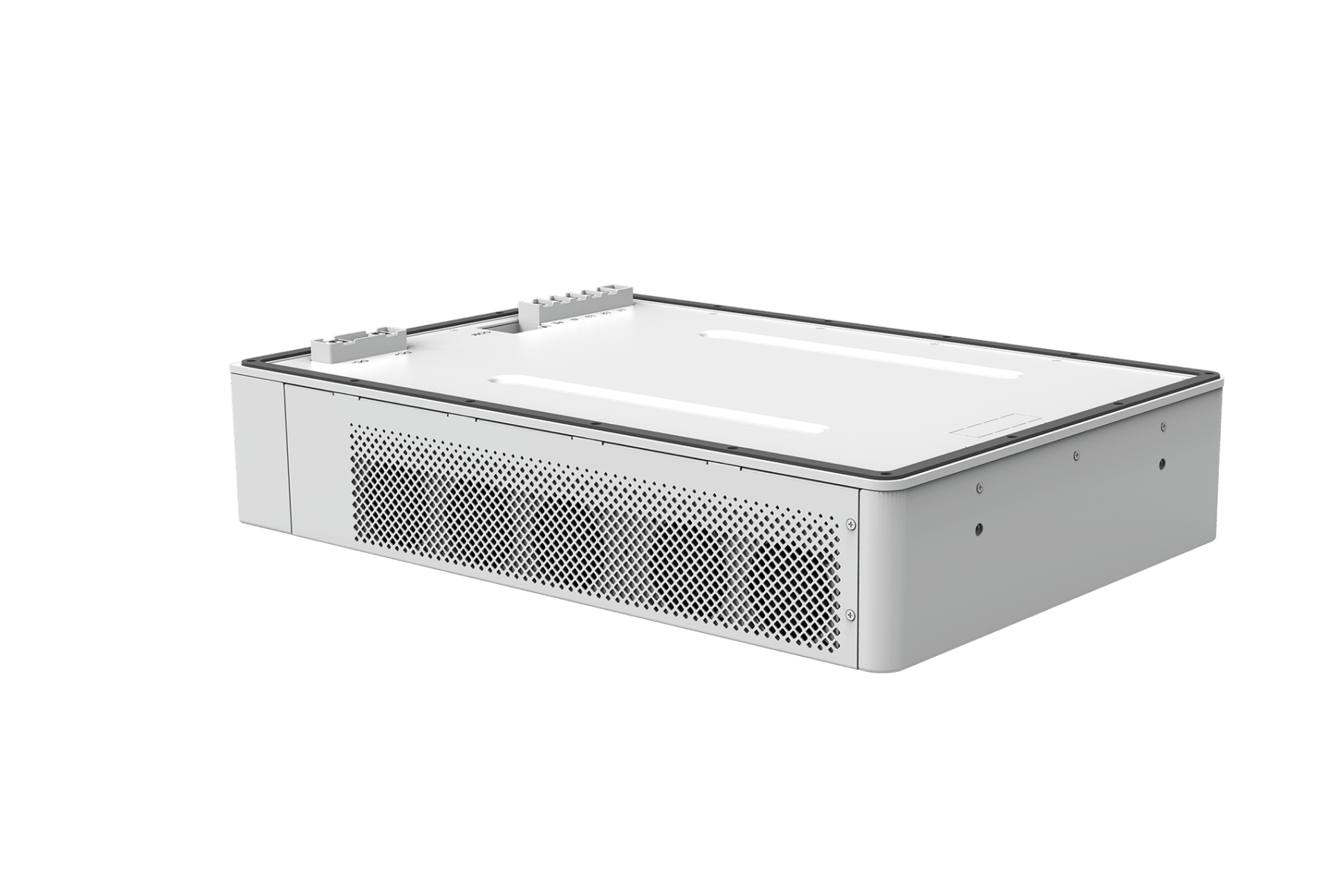

The internal key components are about 10°C lower than that of the air-cooled module. Energy conversion efficiency in lower temperature is higher, and the life of electronic components is longer. At the same time, efficient heat dissi- pation helps to increase power density of the module and can support more modules inside a charging system.

Traditional air-cooled charging system requires regular cleaning or replace- ment of filter screen, regular dust removal of fan, based on different application scenarios. It needs a scheduled maintenance of 6-12 times per year. As a result, the labor cost is relatively high. The liquid-cooled charging system only needs to periodically detect the coolant and clean the radiator dust, simplifying the operation and maintenance work.

Life cycle cost of liquid cooling systems is lower than air cooling systems from the perspective of long term life cycle. Normally, the service life of a conven- tional air-cooled system is 3 to 5 years, and the service life of a liquid-cooled system can exceed 10 years, 2 to 3 times that of the air cooling peer. Air-cooled charging system needs professional scheduled maintenance for 6 time per year on average, and the liquid-cooled system only requires routine inspections. Besides, conventional piles are more vulnerable to malfunction than liquid-cooled charger.